Blog

Star Rapid’s blog aims to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

Top 7 Methods For Making 3D Rapid Prototypes

While 3D printing technology has been around since the 1980s, it is constantly evolving, with new processes being introduced all the time. Some are best suited for consumer applications, while others for industrial environments. However, not all types are suited for rapid prototyping, a technique used to create prototypes quickly

Plastic 3D Printing vs. Metal 3D Printing: CAD Design Differences

A common misconception about 3D printing is that you can use the same CAD design for either plastic or metal. In reality, the processes are very different so design changes will be required. The type of modifications needed will depend on the type of metal 3D printing process being used. We

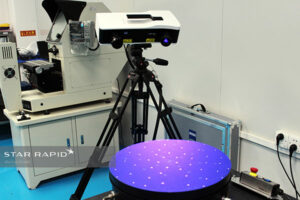

Star Improves Quality with Zeiss Optical 3D Scanner

At Star Rapid, our QC inspection and measurement department is always upgrading to the latest equipment to provide you with the best quality assurance for peace of mind. Here’s how our new Zeiss Comet LED3 2 optical scanner works and how it ensures the accuracy of the parts we make

Improving CNC Machined Parts with Thin Film Coatings

One reason Star Rapid recently partnered with Guhring tools of Germany is because of their proven technology in applying thin film coatings to their cutting tools. Let’s look at why these thin films are so important to tool performance and how this translates into improved quality for the CNC machined

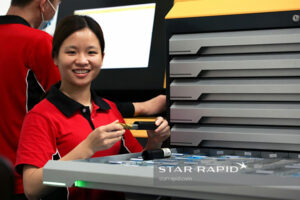

Plastic Injection Molding Surface Finish: Making and Measuring Textures For Injection Molding

All plastic injection molded parts have a surface texture created by the tools that made them. To get the surface finish and texture that you want from injection molding, it’s important for you to learn how we make and measure such finishes in our inspection department. At Star Rapid, we

How is G-Code Used to Make CNC Machined Parts?

What is G-Code? G-code is a generic term for a programming language used to instruct a numerically-controlled machine tool. It controls all aspects of machine movement including spindle speed, the tool path, how fast to move and where to locate itself in a multi-axis space. Why is it Important to