Additive manufacturing offers exciting design opportunities for next-generation parts that need to be strong, complex and lightweight. You can design and build parts that are virtually impossible to make conventionally or that would be prohibitively expensive and time-consuming. However it’s not quite plug-and-play. You should be aware that designing for a metal part is much different than a corresponding plastic one. There are some inherent constraints that are a function of physics, the machine’s particular architecture and the process of metal 3D printing being used. At Star Rapid, we employ a Renishaw AM250 powder bed fusion printer to build fully dense laser welded parts. To help you with your next project, our engineering specialist recommends keeping these design tips in mind which can also be universally applied to any metal 3D printing process.

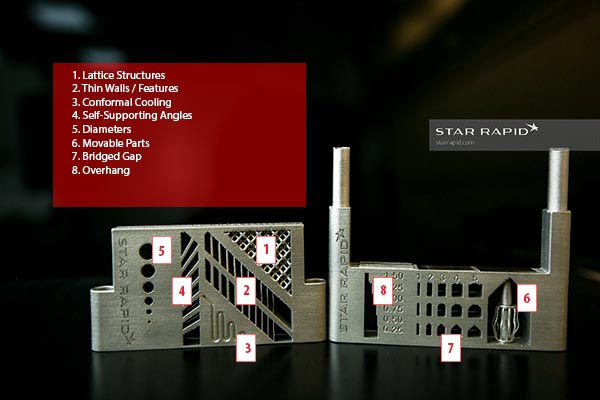

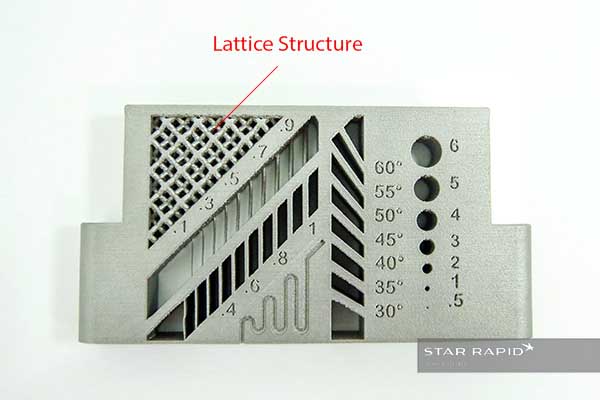

1. Use Lattices to Remove Weight and Preserve Strength

Lattice structures help to remove a lot of mass from solid sections while still preserving strength. We do this by using simulation analysis software to calculate and remove unnecessary material that does not add to the part’s mechanical performance. 3D printing lets you “hollow out” these areas inside of a wall so they won’t affect the part’s finished appearance.

2. Manage Minimum Feature Thickness

Many features like walls and posts will lose resolution as they approach the minimum tolerances of the machine doing the printing. For powder bed fusion this is limited by the laser spot size of 75µm , slightly larger than the powder grain size. The laser spot heats the powder and will create a weld pool that is larger than 75µm. Hence we can produce wall thicknesses down to 150-200µm. We recommend keeping features larger than this to not only to preserve strength but also because features that are smaller are prone to distortion. This may be caused by the rapid heating and cooling of the melting process.

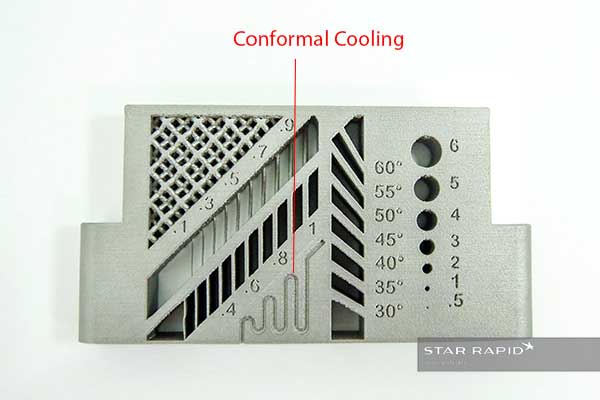

3. Make Use of Conformal Cooling

Conformal cooling channels are one of the great advantages made possible by 3D printing. These can be designed to follow the contours of any internal cavity of an injection mold tool to greatly enhance cooling efficiency and the quality of the finished part.

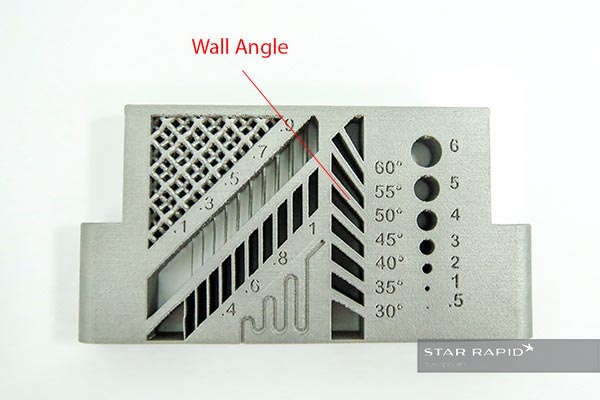

4. Manage Self-Supporting Angles

If a wall or angled support is inclined too much from the vertical plane, it may degrade / collapse due to the pull of gravity.

We recommend an angle greater than 45°. Less than this and the bottom face especially loses resolution or collapses and may need to be post-machined or supported by an additional structure.

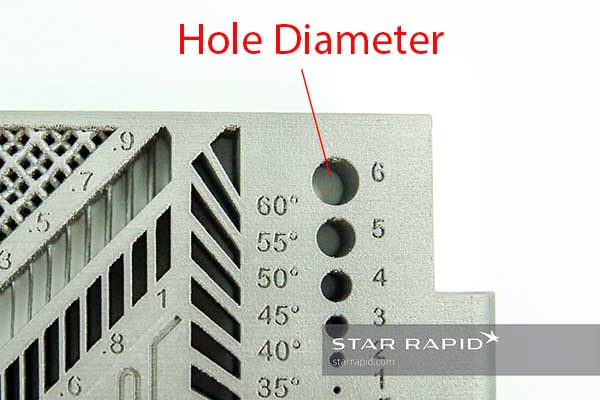

5. Manage Hole Diameters

Hole diameters should be kept to 10mm or smaller so they can be self-supporting.

If the hole is oriented vertically, the upper arc will be unsupported and thus can also deform or collapse. Supports are needed when the hole is more than 10mm. This is a very important design consideration for internal holes where internal supports cannot be removed and thus may affect the part’s functionality.

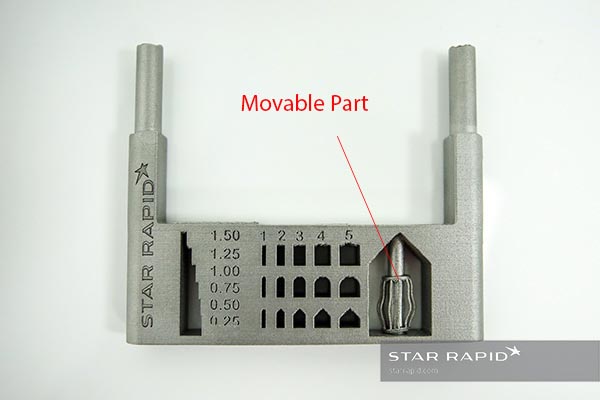

6. Make Use of Moveable Features

Another unique advantage to 3D printing is that it’s possible to build shapes-within-shapes that can move freely after printing.

This opens up a whole new world of design opportunities for complex next-generation electromechanical devices or even innovative 3D printed jewelry which could not be made otherwise.

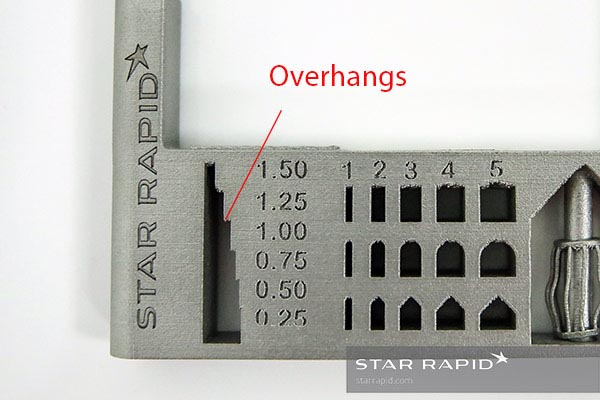

7. Create Strong Bridged Gaps

A bridged gap is like a cut-out, a window or some other pass-through of a solid wall.

If these are arranged vertically they can also deform at the top edge. One way to deal with these features is by re-designing a self-supporting arch structure much like a Roman bridge. A rounded or pointed top will be self-supporting and not require additional supports, but this may necessitate some design changes.

8. Keep Overhangs Below 0.5mm

Overhangs are features that project laterally from the direction of the build. Here the concern is the down surface area, which can begin to collapse if the overhang projects .5mm or more.

There are a few ways to counteract this tendency. The angle between the lateral feature and the vertical face can be re-designed with fillets, either concave, convex or chamfered so that it is self-supporting.

Long overhangs that cannot be supported by a fillet alone may require additional vertical supports. While this method is common and easy to apply, it will take time and money to remove these supports after printing.

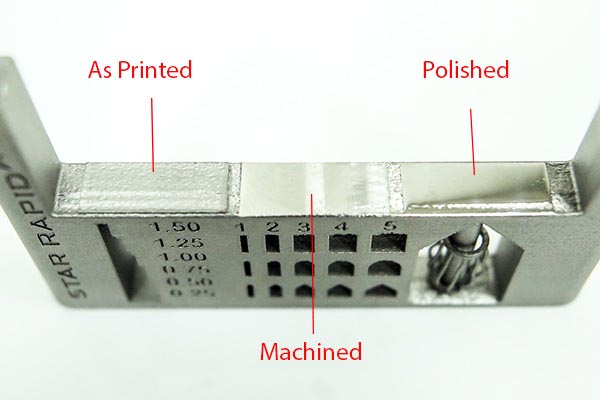

A Word About Surface Finish

Metal 3D printed parts look a little rough when they’re first taken out of the machine. This is because they were created by welding together countless tiny grains of powdered metal. Our parts are fully dense so they can be polished as well as any forged metal piece.

Learn More

Every job is unique and requires expert technical support to meet your specific requirements. We can offer advice on material choices, tolerances, support structures, part orientation, post-machining and much more. Our engineering professionals will work closely with you every step of the way when you contact us for a free quotation on your next project.

Star Rapid no longer offers metal 3D printing services. However, we remain fully committed to helping our customers reach their product development goals by offering a variety of rapid prototyping and low-volume manufacturing services.

If you are looking for metal 3D printing tips, check out our online video tutorials.