Machine Screw Thread Applications for Product Developers

In part one of this series, we looked at the fundamentals of machine screw thread design. This information is invaluable for engineers and product designers, and it’s also a fascinating look at one of history’s fundamental machine tools. Now that we know something about threads and screws in a general sense, it’s time to apply that information to specific applications. The Weakest Link Screws, threaded fittings, […]

What is the Difference between 3, 4 and 5-axis CNC Machining?

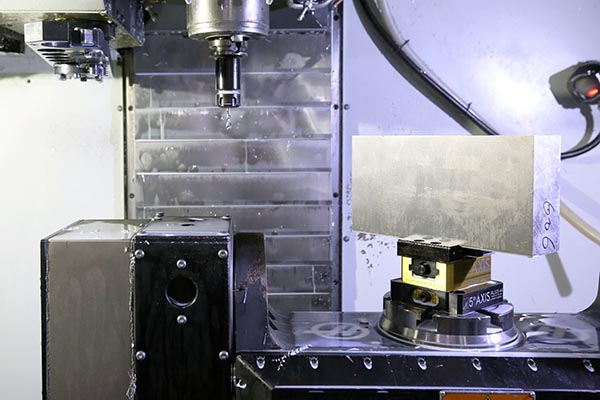

Modern CNC milling machines are amazing tools, capable of making prototypes and production parts quickly and reliably. To do this they must be able to move along several axes of travel while maintaining dimensional accuracy. Blank workpiece before rough milling, mounted on a trammel head for five axes of travel. CNC mills are therefore categorized […]

CNC Medical Machining: Benefits of CNC Machining for Medical Industry Products and Parts

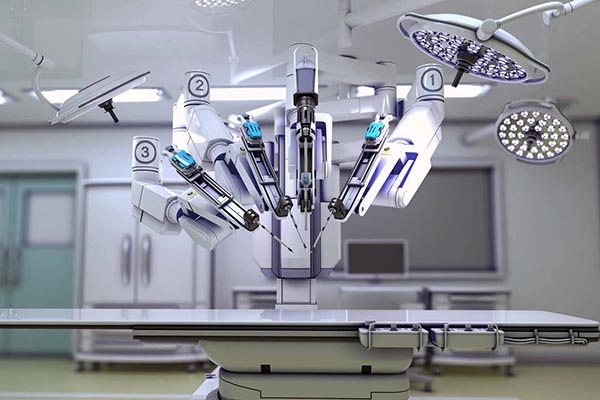

CNC machining, in its many forms, is one of the most versatile of all conventional manufacturing processes. The versatility of cnc machining extends to the types of parts that can be made, the material from which they are made, and the volumes produced. Using conventional CNC milling and turning, parts can be made for medical […]

Infographic – The CNC Machine

We use multi-axis CNC machines every day to perform a variety of milling, cutting, turning and drilling functions. They are accurate workhorses used to make countless products for every conceivable application. Because of their versatility, CNC machines can be configured in a number of ways. Regardless of their configuration or the products they make, most […]

Advanced Vericut Software Improves Your CNC Machined Parts

CNC machines are controlled by sophisticated CAM software that transforms digital designs into solid parts. But not all programs are alike or produce the best results for every design. To optimize your parts Star Rapid has invested in an additional layer of security called Vericut, the world’s leading virtual simulation software for CNC machining. […]

5 Reasons to Use CNC for Rapid Prototyping

CNC Infographic CNC machining for rapid prototyping allows you to leverage the many advantages of computerized equipment to produce fast-turnaround prototypes, engineering models and high-quality end-use parts in the least possible time. Here are the top five reasons to consider CNC machining for your next rapid prototyping project. 1. CNC Machining is Fast CNC machining […]