Color Consistency in Plastic Injection Molding

It’s a big challenge to achieve color consistency for large production runs of plastic injection molded parts. To ensure consistency when molding colors, it’s essential that you have careful process control at every step. It’s important to note that plastic color is highly subjective – subjective in how you see and interpret plastic color. It […]

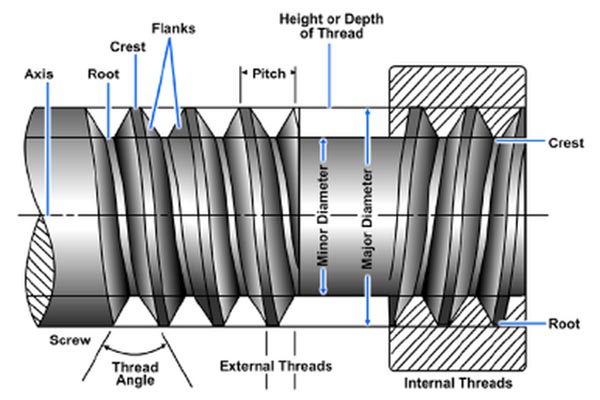

What Every Engineer Needs to Know About Machine Screw Thread Design

Machine screw threads, along with many other kinds of threaded fittings, are used around us every day in millions of applications. In fact, they’re so ubiquitous that they largely go unnoticed by most of us, and to the inexperienced eye they all look and perform pretty much the same. In fact, screw threads are surprisingly […]

Five Rapid Prototyping Solutions For Great Results

Ever since people started making stuff – and then tried to make new and improved stuff – there’s been a need for prototypes. They’re used for design evaluation, testing, certification, proof-of-concept, crowdfunding campaigns and as bridges to full production. If you need high-quality rapid prototypes, may we suggest you consider these 5 well-established and mature […]

The Top 4 Surface Treatments for Production Tooling

TiN coating on mold tool. Image courtesy of prirev.com.All manufacturing tools are subject to incredibly harsh working conditions and must withstand a lot of wear and tear. Tools used for plastic injection molding are no exception, where corrosive resins and abrasive fibers, injected under tons of pressure, can quickly destroy soft or untreated metal. If […]

The 5 Most Common Methods for Applying Textures to Injection Molding Tools

Surface textures and patterns applied to plastic injection molded parts are becoming more sophisticated and complex. These advancements are exciting because they offer so many new design options for product developers and engineers. But before a finished part can be made, the injection molding tool must first be carefully manufactured. So how do manufacturers apply […]

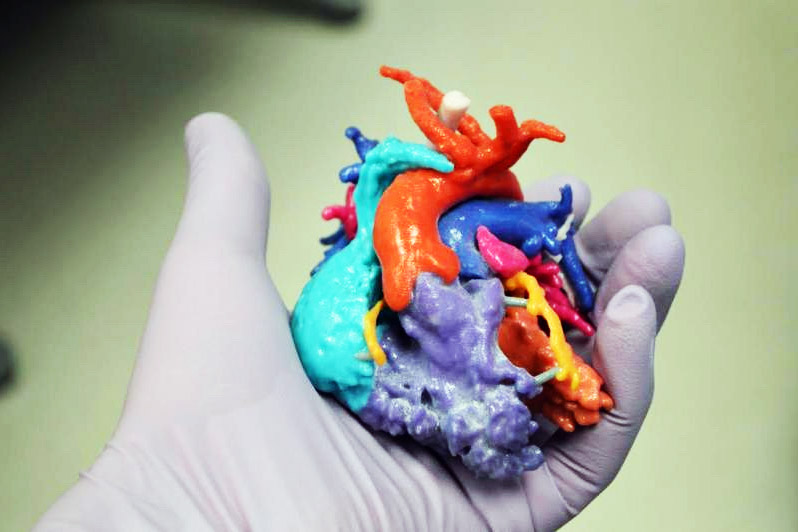

Additive Manufacturing for Medical Applications

The use of additive manufacturing applications is on the rise, with the market value expected to increase from $6 billion in 2017 to nearly $26 billion by 2022. The advantage of additive manufacturing comes from creating complex structures that vary in complexity, customization, lightweight, strength, and speed. As additive manufacturing for medical devices continues to […]