What Makes a Great Paint Job

When people think of paint, they tend to think of it in a general sense. They often picture a smooth liquid substance that—once applied to a surface—can bring walls, buildings, and furniture to life. The definition doesn’t do justice to the sophisticated chemistry underlying modern coating technology. At Star Rapid, we use a variety of […]

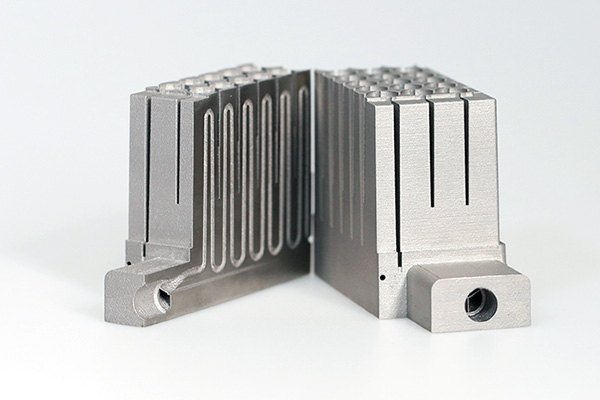

How To Choose The Right Material For Plastic Injection Mold Tools

Plastic caps When considering plastic injection molding for a project, product designers and engineers should consider not only what thermoforming or thermoplastic resin to use but also the choice of metal for the injection mold tool. The choice of tooling raw material influences production lead times, cycle times, finished part quality and cost, among other […]

The Micrometer, Its Parts, and Why It’s Essential for Making Quality Parts

The micrometer helped to create accuracy in modern manufacturing. What is a micrometer? A micrometer is a sensitive tool for making accurate measurements of linear dimensions. It’s one of the most important measuring instruments ever made. It has a rigid C-shaped frame. One side has an anvil that is fixed, and on the other side […]

From Prototypes to Product Launch: Questions to Consider

Prototypes are ideal for testing an idea, improving on the look and feel of a design and for getting a sense of how the market is going to respond. After all, most successful crowdfunding campaigns have started off with prototypes that brought an enthusiastic response which helped fund more development work. But it’s at this […]

Streamline Your Product Quotations with These 7 Tips

When you’re developing a product, you will want to get your manufactured parts completed as fast as possible so you can get the product to market in a short timeframe. To get your project off to a great start, there are some things you can do when requesting a quote from your manufacturing partner that […]

How Pressure Affects Your Plastic Injection Molded Parts

There are many forms of pressure involved in making a plastic injection molded part. We’ve explained the importance of clamping pressure before, so now let’s look at three others: injection, holding, and back pressure. Why is this important to you? Because balancing these forces correctly is one of the keys to making consistently good parts. […]