With thousands of plastics on the market, it can be a daunting task to decide which type is the best for your next rapid prototyping or low-volume manufacturing project. When choosing which plastic to use, there are going to be trade-offs between cost, moldability, surface finish, durability, strength and many others. The choice of plastic depends on not only what the part does but also the environment in which it does it.

To help you understand how different plastics are used, here are some of the most common applications our customers bring to us and the plastic material we would recommend for each.

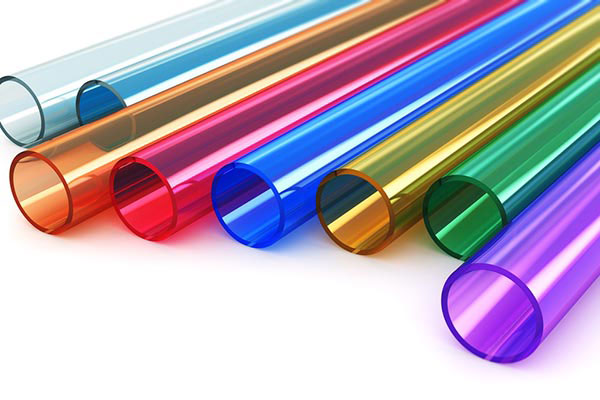

Clear Lenses, Windows and Transparent Parts

What plastics are suitable for clear lenses, windows and transparent parts? We recommend acrylic, also known as PMMA. This material is used to make shatterproof windows like Plexiglass©. It takes a high polish, has good tensile strength and is economical. However, it’s not as impact or chemical resistant as polycarbonate.

If you need something stronger, we recommend polycarbonate (PC) because not only is it more durable it also has excellent optical properties, making it a good choice for lenses, DVDs and bulletproof windows. Another valuable feature of PC is that it can be bent and formed at room temperature without shattering, making it useful for prototyping work not requiring expensive mold tools. (Think of the last time you tried to bend a compact disc in half.) It’s more expensive than acrylic and may release harmful chemicals when exposed to hot water for long periods of time, so it’s not considered food safe.

Mechanical Parts

What plastic resins are best for mechanical parts? One of the most common resins used for mechanical parts is nylon, also known as polyamide (PA). It can often be found as a substitute for simple metal parts in engine compartments where it withstands heat and vibration well. When mixed with molybdenum it has a slippery surface, but nylon-to-nylon gear trains are not a great idea – similar plastics tend to stick together, so it’s best to alternate plastic types. Nylon is well-suited as a filament for 3D printing in plastic, but it does absorb water over time.

Another material we recommend for mechanical parts is polyoxymethylene (POM). POM is a type of acetal resin, used to make Dupont’s Delrin©, a valuable plastic for gears, screws, wheels and other mechanical parts. It’s tough and strong but can degrade with alkali, chlorine and hot water. Also, acetal is notoriously difficult to glue or bond together. It’s often used in alternation with nylon for plastic gear trains.

Tools and Hardware

What plastics are best for hard use, like tool cases and hardware? There are many choices here. High-impact polystyrene (HIPS) is used to make tough cases for tool boxes and the bodies of power tools. It’s inexpensive, one reason why polystyrene is used for disposable packaging, but it’s not considered environmentally friendly.

A better choice might be acrylonitrile butadiene styrene, or ABS. ABS has high impact resistance and is very tough, or resistant to tearing and breaking. It’s lightweight, and can be greatly strengthened by adding glass fibers. It’s commonly found in keyboard keys and Lego© bricks. While more expensive than styrene it also lasts much longer, and ABS is also used for 3D fused deposition modeling of rapid prototypes.

Plastic Containers

What about low-cost, high-volume plastic containers? Polypropylene (PP) is used in food storage containers because it can be washed in hot water without degrading, is resistant to oils and solvents and doesn’t leech chemicals so it’s food-safe. One of its great advantages is that it can readily be formed into a living hinge, like you commonly find on the cap of a bottle of aspirin. This type of joint can be bent repeatedly without breaking. It also finds wide use in pipes and hoses.

Polyethylene (PE) is not especially strong, hard or rigid but is still the most common plastic in the world. Usually found in a milky white color, PE is the plastic found on medicine bottles, milk and detergent bottles and trash cans. It’s very resistant to various chemicals but has a low melting point. Because it’s so elastic it’s also used for plastic bags and cling film.

Toys

What’s a good plastic for making children’s toys? Almost one-third of all the plastic toys in the world are made from PE , since it’s inexpensive, non-toxic and very colorfast. Additional UV stabilizers can be added for outdoor and recreational toys that will experience a lot of sunlight.

Stronger and more rigid toys with higher impact strength are made from ABS or nylon.

Rubber

Which plastic resins are most like rubber? Many applications call for injection molding of resins that have the soft, elastic properties of rubber. For this we use thermoplastic polyurethane, also known as TPU. It comes in many special formulas to achieve high elasticity, low-temperature performance and durability.

TPU is used in power tools, caster wheels, cable insulation and sporting goods, among many other applications. It’s solvent resistant so it can be found in many industrial environments. However, TPU can be tricky to process because it is notorious for absorbing moisture from the atmosphere.

Finally, for over-molding there’s thermoplastic rubber (TPR), which is inexpensive and easy to handle for things like cushioned rubber grips.

What Kind of Product Are You Making?

The above is just a brief overview of some of the common plastics we use at Star Rapid. All of these can be modified with various glass fibers, UV stabilizers, lubricants or other resins to achieve particular engineering properties according to your special needs when required. Check out the full material list and their properties for plastic injection molding, vacuum casting, and CNC machining.

If we haven’t listed the kind of product you need a plastic for, just leave a comment or contact us and we can let you know what choices are available.

When you’re ready to start your next plastic injection molding, CNC or vacuum casting project, send us your 3D CAD files for a free quotation and we’ll help you to find the best plastic that’s right for you.