The process of painting beautiful parts

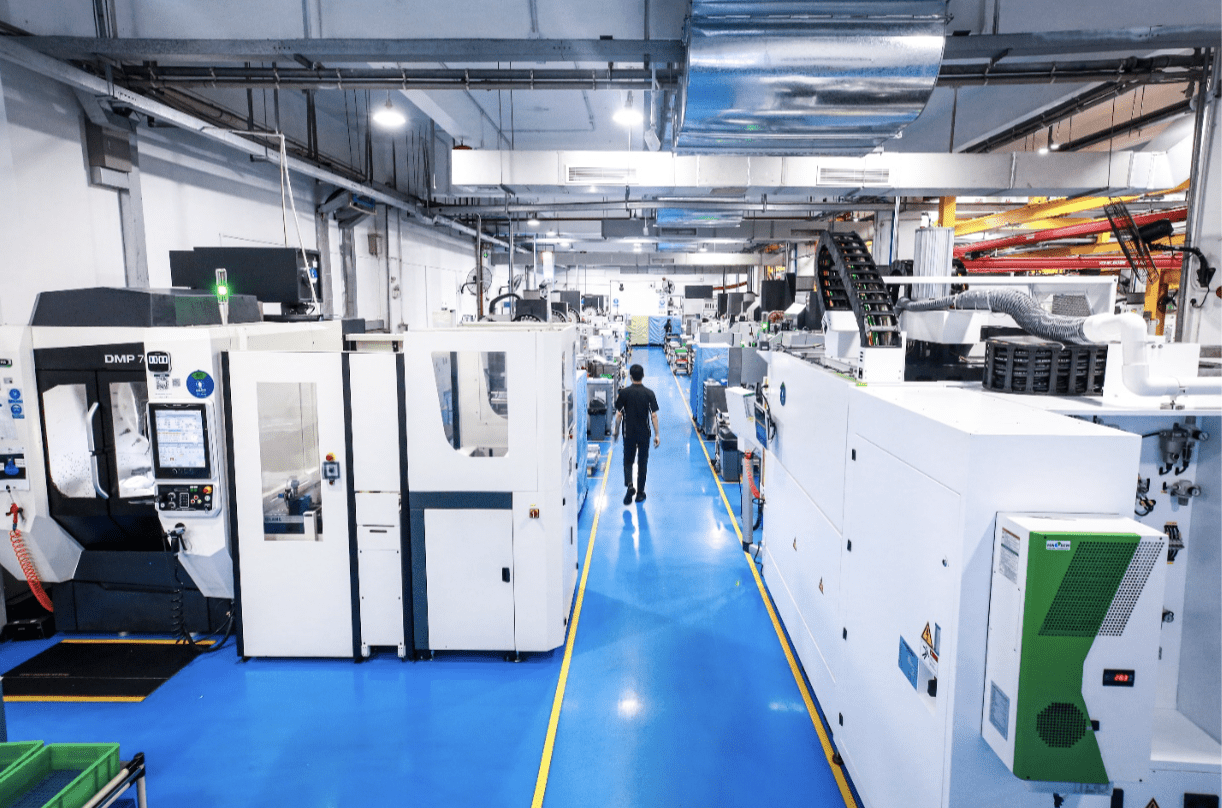

There are some unique challenges that present themselves when trying to achieve the perfect paint finish for prototypes or low-volume production. High volume batch production can be automated to produce large runs of identical parts, but small batches must be carefully handled on a case-by-case basis. Let’s take a closer look at how the team at Star Rapid controls the painting process with its clean room painting facility so that you get exactly the color and surface quality you were expecting.

First, a brief word about the difficulties of matching colors. There are many systems for determining and standardizing colors, among them the familiar Pantone® color matching system, RGB (red, green and blue), and CMYK (cyan, magenta, yellow and key – black). More details on that here: https://en.wikipedia.org/wiki/CMYK_color_model. Each of these color spaces is independent although there is some overlap between them. Millions of color combinations are possible. And if you also include variations like pastels, metal flake and fluorescents, you begin to understand the challenges incumbent upon the painting specialist.

To ensure high quality and repeatable results, we implement strict guidelines in our painting process.

Whenever possible, the customer provides us with a known color value to apply to their part. This can be a Pantone® number or a CMYK/RGB value. LAB color values are preferred. More on that below.

We have a complete set of color books and sample cards that are continuously updated which makes color matching relatively easy when precise values are specified. All painted surfaces will fade or degrade over time due to the effects of UV light. Therefore, Pantone® books and other color chips must be renewed to ensure accurate color rendition.

We ensure that the color specification is written on the customer’s purchase order to ensure it becomes the reference for our painting specialist to match.

In some cases, however, there is no specific value and there is instead only a physical sample or chip as a reference, and this creates something of a challenge.

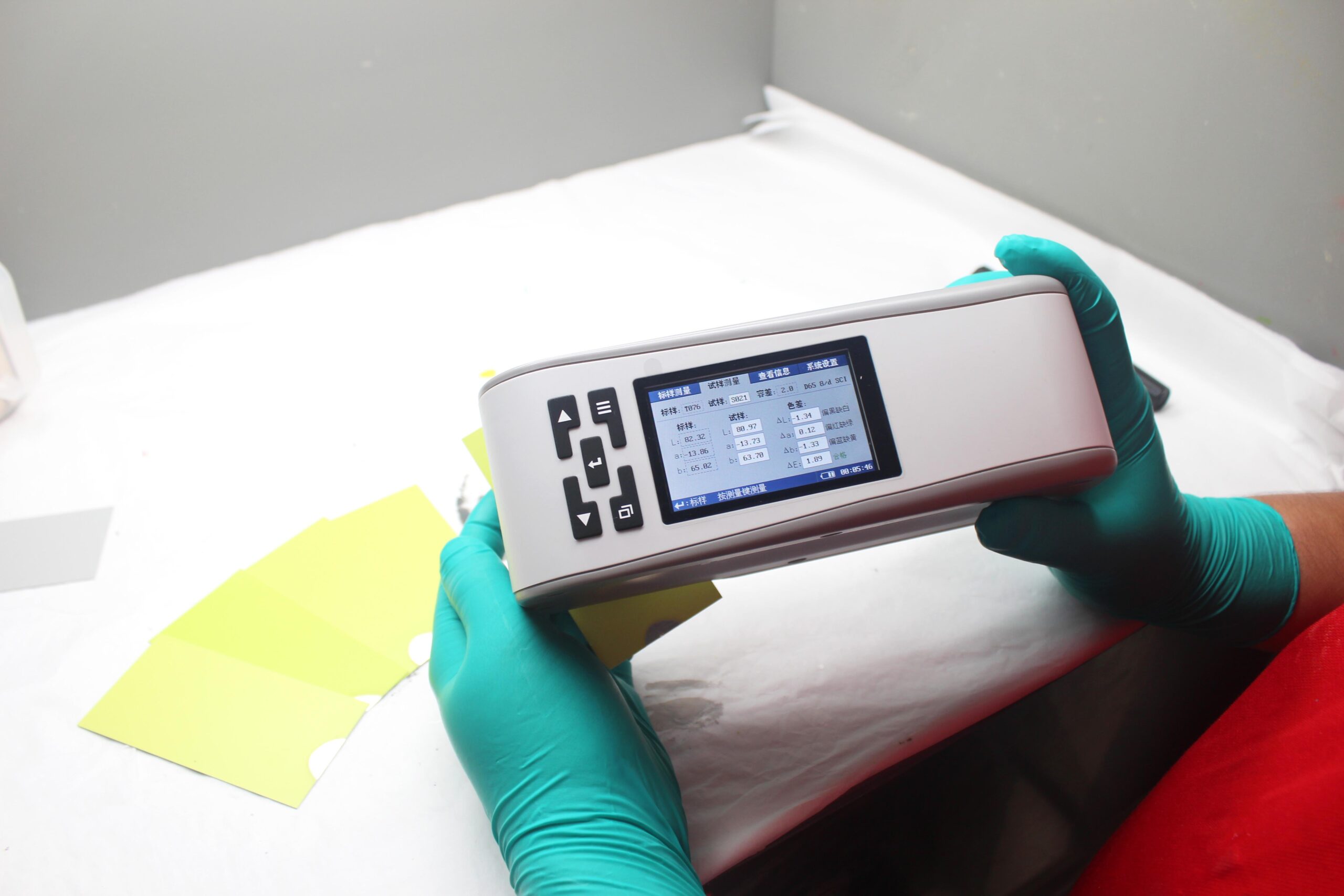

If the part has a flat face, then a color spectrophotometer will be used. The spectrophotometer bounces a white light off of the surface and is able to read the reflected light coming back through a series of color filters.

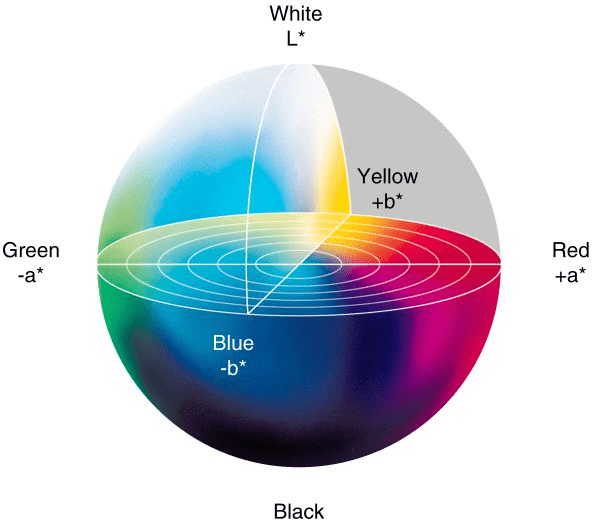

The results are computed in terms of the LAB color space, which has one coordinate for luminosity (L) and two coordinates for color (“A” is red to green and “B” is yellow to blue). The combinations of these values produce all known colors.

On a curved surface or a very small part the photometer may not work, in which case the craftsman must use their experience to make a “best guess”.

The painter will mix the primary colors in the correct ratio, adjusting as necessary to achieve the desired result. This takes experience and cannot be automated due to the many inherent variables involved.

Once the matching color has been achieved, a sample of this part is sent to the customer for approval.

This is often problematic, since there are many variables that control the perception of color, including the eyes of the person doing the viewing, the ambient lighting conditions, the colors and brightness of the surrounding environment, the viewing angle, etc.

- If a non-quantifiable method is being used (i.e., subjective judgment from the human eye), then the precise viewing conditions need to be specified and agreed upon in advance. It is recommended to use a color-balanced inspection booth with a Philips D65 source or equivalent.

- In the case of using human judgment, it may be necessary to qualify the accuracy of the viewer’s eyes via an online vision-testing tool or another agreed-upon method.

If the color is approved, a large batch of the initial mixture is marked and placed in storage to provide the basis for any future paint batches, if necessary.

The part is cleaned with the correct thinner. Different thinners are used for different grades of plastic or metal.

The entire paint booth area is climate-controlled with a dust shower to ensure non-contamination of parts.

The parts are placed on an automatic conveyor system where they enter the spray booth.

Careful attention is paid to insuring the spray guns are clean and free of obstruction. They must be carefully adjusted to apply the correct amount and pattern of paint droplets with the right pressure.

Positive air pressure inside the spray booth keeps dust out! All outgoing fumes travel through multiple filters and the resulting air is cleaner than the outside atmosphere.

Parts receive multiple coats, first a thin mist to establish a base coat, and then thicker top coats.

Freshly sprayed parts are loaded into a drying oven for one hour, then allowed to fully cure at ambient air temperature for at least another 8 hours.

The choice of what chemical formulation of paint to use is as important as the choice of color. Our project managers work closely with the customer to determine the conditions under which the part will be used. The ideal choice of paint formula must account for the following considerations:

- Durability and abrasion resistance

- High-visibility

- UV stabilization

- Corrosion resistance

- Surface grip / texture

We offer the high-quality PPG Global Finishing System of paints, comprising primer, toner and two coats of polyurethane paint. Other paints available on special request.

Our goal is your complete satisfaction with the final surface finish of your part, and we invest heavily in equipment and training to ensure the best service in our industry. Do you have a project you’d like help with? Contact us to learn more about how we can help you.