Virtually all new products intended for the medical industry start out as prototypes. Prototypes are used for proof-of-concept, engineering testing, certifications, benchmarking and as design models. And for this purpose, vacuum casting is the ideal rapid prototyping service when preparing a product for high volume production, especially with plastic injection molding.

Because injection molding requires a dedicated solid metal tool, it’s good advice to first create a few prototypes using vacuum casting. This helps the product engineer to perfect the design before committing to an injection mold tool. Prototypes made with vacuum casting are very high quality and in many cases can be used for full engineering testing.

Let’s take a closer look at the advantages of polyurethane vacuum casting when preparing a new product for medical applications.

1. Vacuum Casting Is Fast

First, it’s important to note that all vacuum casting operations begin with a master pattern. This pattern is a solid replica of the intended final part, often made with 3D printing or CNC machining.

Once the master pattern is ready, a mold can be made from it in less than two days – one day to pour the silicone, another day for full curing. This is much faster than it would take to make a plastic injection mold from steel or aluminum. And, once a mold is ready, resin can be poured into the cavity to make a finished product in another two days. Taken together, the development process from concept to finished product – including making the master pattern – can be done in less than one week, sometimes even much faster than that.

2. Vacuum Cast Parts Are High Quality

Resin cast copies of master patterns demonstrate excellent fidelity to the original pattern. This includes not only dimensions and tolerances but also fine surface detail and texture. That means that resin cast prototypes can look and perform almost exactly like production quality plastic injection molded parts. They can also be post-machined just as with any other solid part.

This excellent surface texture also makes it easy to apply a final paint finish without needing extra sanding or polishing preparation.

3. Multiple Materials and Overmolding

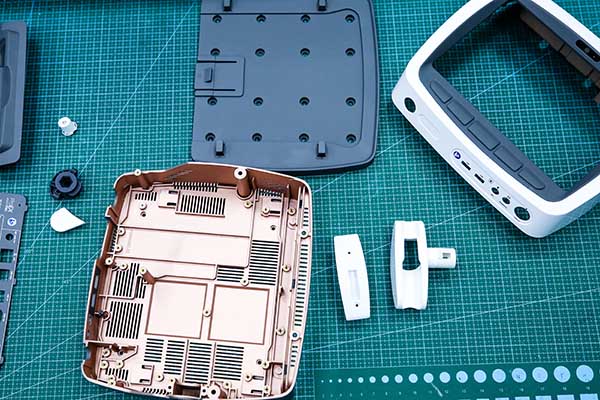

Medical products often come in the form of cases or enclosures that use panels, screens, buttons, keypads, and other interactive elements. This is more common as medical equipment become increasingly digital and interconnected.

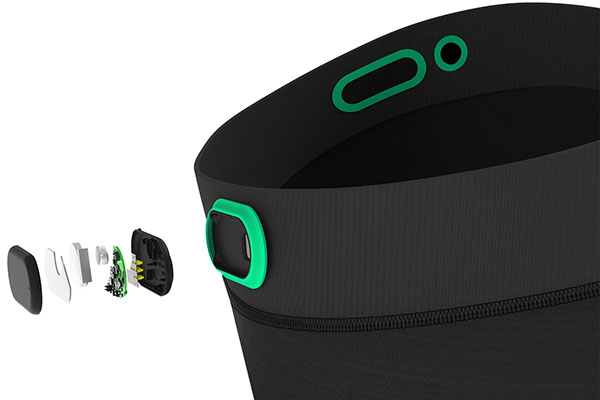

And these control surfaces and keypads often use soft elastomers or other rubber-like materials as overmoldings. It’s possible to mold two or more dissimilar materials into a single finished piece using vacuum casting. Of course this can be done with injection molding but it’s a much more expensive and time-consuming operation that requires separate hard tools.

4. Many Types of Plastic Are Available

Products used in a healthcare environment must exhibit many different kinds of chemical and mechanical properties. They may need to be strong, rigid, heat and chemical resistant, biocompatible, transparent, easily cleaned and sterilized, etc. To meet these needs, there are pourable casting resins available that can match all of these qualities and more. This is especially beneficial when preparing a new prototype idea for medical certification such as is required by the FDA.

5. Vacuum Casting Is Affordable

It is always important to control costs at every stage of production and this also applies to prototyping. Making a master pattern for vacuum casting, as well as making the silicone molds and the resin copies, is a small investment. In most cases it requires a much smaller initial investment than alternate methods such as 3D printing or CNC machining. This savings can then be applied to further product development and eventual full production.

6. Molded-in Color

Another unique advantage of vacuum casting is that resins can be colored with dyes and pigments just before they are poured into the mold. This yields a finished product in any color so it doesn’t require further painting. This is unlike injection molding, where the product developer needs to commit to a minimum volume of raw material that can be colored with master batch pigment.

Ready to start your next project?

We’re experts in vacuum casting and prototyping. You can learn more about our other successful projects in these case studies for remote health monitors and wearables. We’ll offer you expert advice about what process is best for your medical products when you upload your CAD files for a free quotation today!

Tagged: