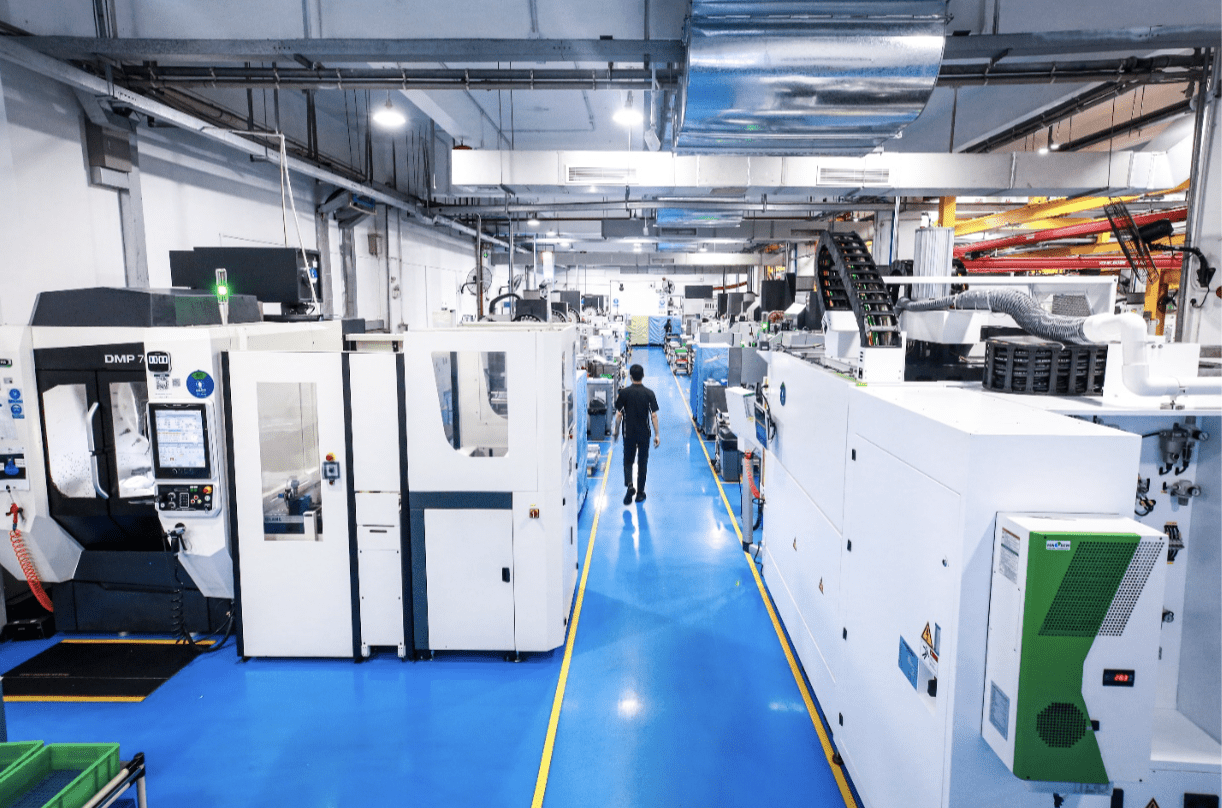

At Star, we are always looking for ways to improve speed and quality. One way we’ve done this is by partnering with the tool company Guhring to ensure that we provide only the finest tools when making CNC machined parts and rapid prototypes.

Guhring is a German manufacturer of carbide and PCD cutting tools like drills, reamers, taps and mills for the machining industry. Guhring is a world-class manufacturer of round shank cutting tools for the metalworking industry and a provider of top-quality coating, reconditioning and tool management services. More than a century of expertise in cutting tool manufacturing, combined with powerful R&D resources, place Guhring at the forefront of technical innovations in cutting tools. Globally there are more than 70 production plants and service centers, along with hundreds of knowledgeable technical support experts, providing Guhring products and services to the industry.

We’ve contracted with Guhring to provide us with four exclusive advantages that ultimately will improve our service to our clients.

Custom Tool Management System

Tailored to our needs, a Guhring tool vending machine offers tool storage, inventory control and real-time monitoring of tool consumption. This lets us anticipate future tool usage so we order only what we need when we need it. We therefore experience a reduction in downtime due to missing cutters as well as reduced cost associated with excess inventory. All of which means a saving in time and money for our customers. But the Guhring Tool Management Software (GtMS) which controls the vending machines offers us much more features than only maintaining the stock, like collecting actual tool life data and its automatic evaluation, managing our measuring equipment including the supervision of the calibration dates or support the maintenance management of our CNC machines. This all leads to a higher usage of our machines and enables us to guarantee in-time delivery to our customers.

For the development of the GTMS Guhring has a separate IT-department and can therefore realize our future demands for additional features with shortest lead times and by that support our development in the area of industry 4.0.

Surface Coatings

Cutting tools are exposed to high temperatures, extreme friction, vibration and chip adhesion. All of these can severely limit tool life, but this can be improved with the careful application of thin-film vacuum deposited coatings. These coatings reduce friction, dissipate heat and keep cutting edges sharper, longer. Guhring has a family of proprietary coatings specially formulated to match not only the tool type but the properties of the raw material it’s most suited for. Guhring has its own R&D department to develop and improve the coating by themselves.

Regrinding Expertise

Guhring will not only be our vendor for new tools but will supervise sharpening and regrinding services on the tools we have now. How is that an advantage? Since Guhring already knows the metallurgy and the complex geometry of each end mill or cutting insert, we don’t need to worry about working with an outside vendor that may not understand how to process sophisticated metals with advanced coatings.

After all, such tools can be highly engineered and very expensive. Preserving their service life for as long as possible saves real money and downtime on the shop floor, which is another savings that benefits you.

On-Site Technical Support

Guhring will have a technical expert on site at our Star Rapid facilities every day, working directly with our machinists to help them optimize “speeds and feeds” for every cutter. This will help us to increase our cutting speeds which reduces total processing time and cost, while providing the best possible surface finish on your parts.

They will also be our liaison for ordering replacement parts, solving technical issues and testing new and improved cutters when they become available directly from the factory. Customers can therefore rest easy knowing their products are being made with high-quality cutting tools that hold precise tolerances for excellent results on machined parts.

The combination of these four benefits means real savings for our clients while enhancing peace of mind. Our strategic partners have a vested interest in growing with us and the best way to do that is by offering superior service to our clients. And we’re convinced that when our customers understand our investment in continuous process improvement through such relationships, they’ll trust us to be their manufacturing partner too.

Want to know more? Upload your CAD file today for a quote and project review and see how we put these advantages to work for you on your parts.