Head to an entrepreneur conference and every other person will most likely have a story of failed venture. Some stories are more fascinating than others with different reasons for failure and lessons learned. When you’re standing in your shower that one morning and the light comes on in your head – that eureka moment – I’m sure one of the last things you’re thinking about is how you’re going to produce this groundbreaking product idea you just thought about.

In many ways that’s a good thing. Setting up your own business venture and manufacturing your idea is a massive task that requires blood, sweat, tears and some starting capital. You will be told that you need to prototype your product to make sure that it works. But before you dive into the world of rapid prototyping, there’s one step that quite a few startups miss out on: creating a proof of concept. A proof of concept differs from a prototype. With a prototype you aim to show a functional, if not perfect, iteration of your end-product. A proof of concept is to show that something can be done at its most basic level – regardless of level of functionality.

Presenting a proof of concept alongside your budget and business plan can be part of a make-or-break moment when standing in front of a potential investor. If you’re looking at setting up a venture that will entail a physical product, creating a proof-of-concept can be done quickly and inexpensively. Methods vary, from CNC machining to vacuum casting. Sometimes you can start the process by yourself with everything from cardboard to wood or other items you can find around your home or office.

Providing a high-quality proof of concept to a potential investor gives them something tangible, something they can touch, and can add an extra layer of confidence in your ability to deliver and be a successful business partner.

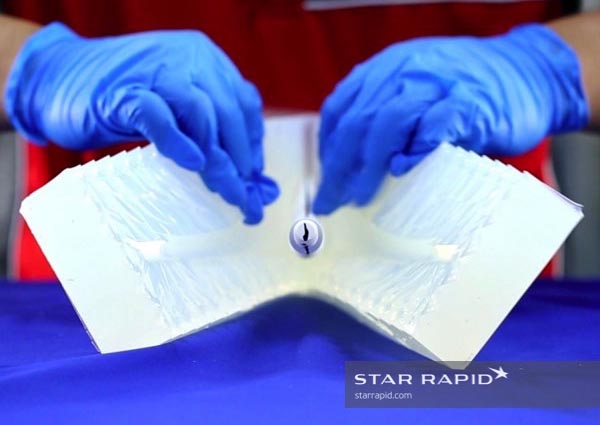

Vacuum Casting Offers a Quick and Affordable Option

One of the most popular methods for proof of concept production is vacuum casting. It’s a low-cost and reliable method for making a small number of high-quality plastic proofs of concept items of your business idea. By creating a master mold you’re able to produce up to 50 copies of your product at a very low cost. The molds allow for a fine surface finish whilst still being robust. Vacuum casting is great for using different types of plastic including ABS, PP, Acetal and Rubber.

Sometimes getting a business up and running is about speed. Making sure that you beat a potential competitor to the market or securing investors can be real make-or-break moments for any budding entrepreneur. That’s where the speed of vacuum casting for proof-of-concept is nearly unbeatable.

When pitching your idea a minor detail can be the difference between success and failure. When creating your proof of concept with vacuum casting you’re able to make a potential product pop by using a range of finishing surfaces such as sanding, painting, polishing, pad printing and many more. This allows you to put forward a proof of concept that can feel as close to the real product as you will ever get.

The benefits of creating a proof of concept go beyond the ability to dazzle an investor. It can give you an opportunity to further iterate your design. This could potentially improve the final outcome of your product when it goes to production. Design iteration with a life-sized sample in hand can be extremely effective and highlight issues which need to be rectified as well as selling points about the product which were not originally considered.

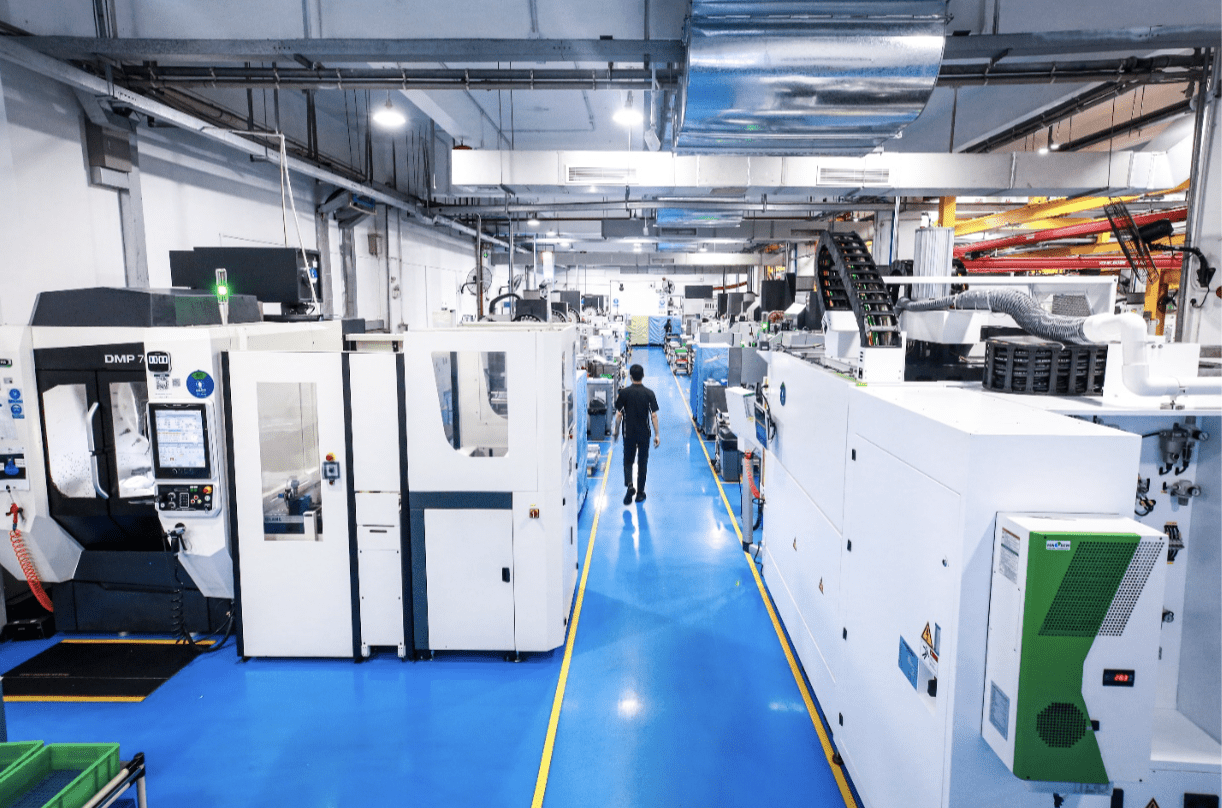

At Star Rapid we offer high-quality vacuum casting services alongside a wide range of other manufacturing methods. We also offer a variety of finishing services. So why don’t you submit a free request for quote to make your product idea a reality.