As a product developer, you may be wondering how you can verify the integrity of your supply chain during these uncertain times, with so many quarantine and travel restrictions in place. While it may be difficult or even impossible to visit a supplier in person, there are still some things you can do to help you perform your due diligence for supplier verification even from a distance.

Industry Reputation

If your supplier has an established track record with other reputable companies, as well as a recognized brand name, this will obviously go a long way towards establishing credibility.

Check if they have a presence on major search engines. What about on social media like Facebook and Instagram, or a B2B platform such as LinkedIn? Many companies who are thought leaders in their market may have a social media presence with regular feeds, updates, white papers, blogs or other content that establishes their authority. And don’t forget YouTube, which is one of the most popular platforms where manufacturers can demonstrate their capabilities.

Patents

Innovative companies are able to create unique solutions for their customers. Having a history of patented innovations shows that your supplier is both technically competent and can be counted on for their dedication.

Functional patents, like those at Star Rapid, are one reason we are a recognized leader for our Research and Development initiatives.

First Article Inspection Reports

After the first sample of a given item is made, insist on receiving a complete initial inspection report. Only when you approve of this report will your order be fulfilled.

This report is an excellent way to gauge how careful your supplier is when checking and reporting on physical dimensions and tolerances. After all, one of the secrets to making great parts is knowing how to measure them, and this is the first step.

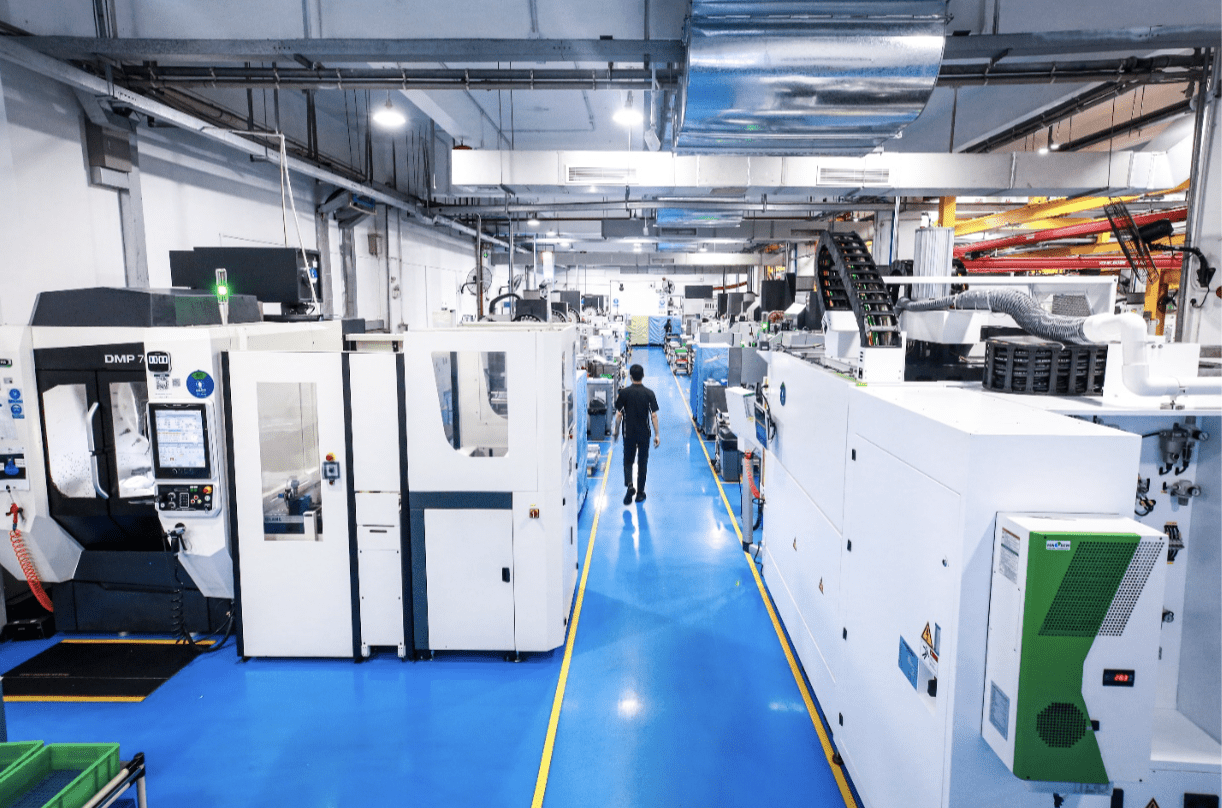

Machinery, Equipment and Supplies

As with measuring and test equipment, ask for a comprehensive machine list showing all of their manufacturing capabilities.

Talk with your sales representative about supplies and support equipment as well. This group might include such things as cutting tools, holding fixtures, lubricants, abrasives, etc. Why is this important? If your supplier invests in quality materials – even for things easily overlooked like sandpaper or adhesives – that means they pay attention to the details and don’t cut corners. That’s a good sign that they’ll pay due attention to your order as well.

Safety, Cleanliness and Hygiene

We are all especially aware these days of the importance of good sanitation, hygiene and public safety. We should expect this for not only ourselves but also the people with whom we work – even if they’re on the other side of the world.

Find out what protocols your supplier has in place for maintaining a clean and safe workplace. Find out how they keep records and demonstrate that they are following the best public health practices to safeguard their workers and staff. Again, attention to detail and a comprehensive, well-organized defense is a perfect demonstration of world-class professionalism. You can expect such a supplier to apply the same standards to the work they perform for you.

Lean Manufacturing

Implementing a lean management system demonstrates your supplier’s commitment to constant improvement.

Kaizen, 6S and other lean management tools help a supplier to constantly focus on core disciplines that include safety, on-time delivery, quality and waste reduction. All of these ultimately enhance your supplier’s performance and the value of the service they can provide to you.

Learn More

Star Rapid has a comprehensive library of information and resources you can use to verify our capability and quality even if you cannot visit us in person. This includes case studies, white papers, blogs, videos and more. Contact us today or upload your CAD files for a free quotation to see how we can support you with rapid prototypes and low-volume manufacturing.