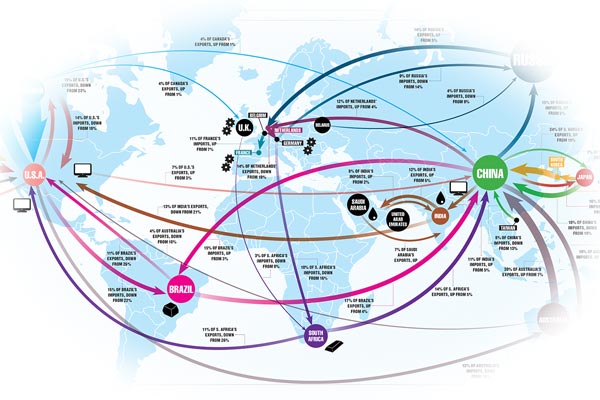

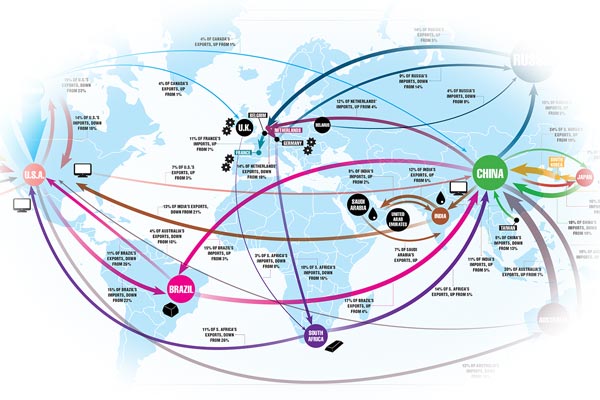

There are tremendous new opportunities opening up for product developers, entrepreneurs and manufacturers around the world due to the increasing pace of globalization. Here are, in our opinion, the top three effects globalization is having on manufacturing and how our team thinks manufacturers should deal with them.

1. Trade Agreements

Free trade agreements can be beneficial to both manufacturers and consumers in the participating nations by opening access to markets and goods. If you happen to be sourcing from a supplier located within a trade zone favorable to you, this may be a great chance to save money by avoiding import duties, as is the case with agreements like the new CHAFTA legislation between China and Australia.

But such agreements are also subject to sudden changes due to political and market forces over which both consumers and suppliers have no control. A business relationship that was a great deal yesterday may suddenly be upended overnight if tariffs increase, certain commodities are blocked, or currency valuations fluctuate dramatically – all very real possibilities in a global economy. Is there a way you can protect yourself in the long-term?

Your best bet is to always work with companies that represent lasting value based on sound management principles. This means low-overhead, high quality and fast response times. Business cycles come and go, and trade agreements sometimes work for you one day and against you another. But if you stick with manufacturing companies that provide universally valuable service and delivery you’ll always come out ahead in the long run.

2. Environmental Regulations

As with free trade agreements, international treaties have been drawn up to join nations together to address pollution, resource depletion and climate change.

The best global companies don’t see environmental protection as a regulatory burden and neither should you. Rather, try to work with manufacturers that treat environmental responsibility as part of their core business practice. This involves asking about the following:

- Have they upgraded their machinery and equipment whenever possible to be more efficient while making a smaller carbon footprint?

- Have they streamlined their procedures to reduce waste and unnecessary or repetitive work?

- Do they recycle, re-use or up cycle materials to keep them out of the waste stream, which also reduces material costs?

- Have they partnered with independent, third-party certification bodies like ISO to document and maintain high standards for health, safety and environmental controls?

- Have they replaced hazardous or non-biodegradable supplies with “green” alternatives?

Companies using best practices for environmental management are sure to demonstrate the same kind of due diligence in managing the rest of their business, so this is a great way to find a manufacturing partner that is not only green but also dedicated to employing world-class standards in all of their operations.

3. Responsible Sourcing

Because of globalization, raw materials are routinely sourced from, and shipped to, many places around the world. As the supply chain extends across continents, it can be difficult to know exactly where material originated from and whether it meets all international standards for compliance with environmental regulations and honest trade practices. As a responsible buyer, how can you be sure of the integrity of the resources you consume?

Ensure your supplier employs rigorous in-house testing and verification procedures for incoming raw materials. This is the only way to guarantee that the materials used on your project are up to spec, legal and of high-quality. And some markets require proof that your products contain no banned substances like lead or cadmium, as with RoHS regulations in Europe. A responsible supplier will have no problem providing verification that will give you complete peace of mind.

In the global marketplace, you want to be a good global citizen. So be wary of any supplier who can’t or won’t give you this degree of confidence that they take their responsibilities seriously.

The benefits of Globalization in Manufacturing

Globalization continues to make possible the worldwide exchange of new technologies, finished goods and even new ideas. The pace of change is ever-increasing, so to keep up with it requires careful planning, foresight and working with the right manufacturing partners. If you want to take full advantage of the expansion of global trade you should look for companies that are flexible, rapid to respond to changing conditions, and above all demonstrate a commitment to providing world-class service and support. Those are universal values that will always be sought after in a global marketplace. When you contact us for a free quotation and project review, you’ll receive this same level of service and much more.

Tagged: