When you supply your 2D and 3D drawings for a quotation on a new project, you must specify the dimensions for critical areas on your parts, as well as the tolerance that you require. Very tight tolerances are neither practical nor desirable in most instances, so let’s look at the tolerances that we specify at Star Rapid for most projects, why we do that and what it means for your parts.

What Is A Tolerance?

A tolerance is quite simply the acceptable deviation away from an exact measurement or dimension. It’s usually expressed as a “+/-“ value. If your dimension is 50 mm on a given feature, the tolerance will be some number a little above or a little below. 50.1mm ~ 49.9mm represents a +/- tolerance of 0.1mm, but sometimes a tolerance is also expressed as +0/-.2 for example. In a case like this, the specification says that a given feature cannot be any larger than the nominal value, but it can be a little smaller.

Since there will always be some possible movement and it must be accounted for, we need to find a compromise about how much tolerance is acceptable, at minimum cost and in a minimum time frame. Perfection isn’t possible, so instead we need a standard.

What Is ISO 2768-1?

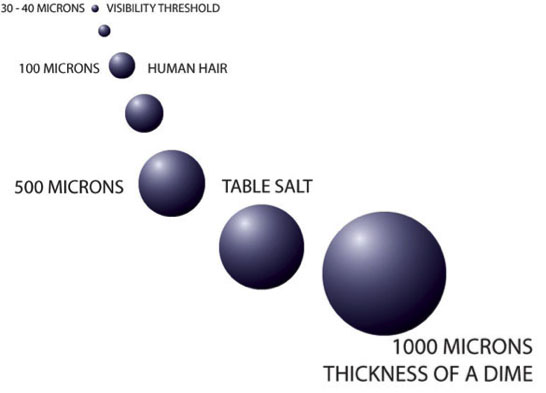

This is the industry standard for determining tolerances, covering linear and angular dimensions, radii, flatness, etc. At Star, we verify our CNC machining operations to hold a tolerance classification of ISO 2768-1 fine (for metals) and medium (for plastics). The closest tolerance in this classification system is down to 50 microns, or .002 inches. That’s pretty small.

This is what you can expect on most projects that we quote, and for the vast majority of applications this is more than good enough. This standard was arrived at by consensus from manufacturers all over the world, making millions of parts every day. It’s reliable and repeatable on modern CNC machines using high-grade materials and cutting tools, so it’s the bottom line for what constitutes quality manufacturing for mass produced goods.

How Will Tolerances Affect Your Part?

What do these numbers mean in how your part is going to look, feel and perform? ISO 2768-1 fine will ensure all the holes, features, slots and mating faces are in the right location. Screws will go smoothly into their mating threads, without free play (too loose) or without binding (too tight). Covers will close flat with a nice even seam all around. Parallel will be parallel, and perpendicular will be perpendicular, all to a degree that more than meets most normal expectations in the real world. And honestly, in the vast majority of cases, you don’t want closer tolerances than this.

Why Are Tight Tolerances Not Always A Good Thing?

All materials expand and contract with changes in temperature. They may also distort under load, move due to vibration or wear over time. So even if a feature or dimension was manufactured “perfectly” in a factory, it would not be perfect once it was put to use. This is a reality for all objects that need some free play to fit together and pull apart.

Also, from the manufacturer’s point of view, chasing perfection in any one feature – say the location of a screw hole – means losing it somewhere else. Microscopically small, incremental improvements in tolerances are exponentially more difficult to achieve in production work. They require specialized equipment, climate-controlled clean rooms, much longer processing times and much higher costs. This kind of investment may be necessary for sophisticated scientific instruments, luxury watches or aerospace components but is rarely required or advisable for rapid prototypes or low-volume manufacturing.

What Tolerance Is Best For Your Project?

That will depend of course on exactly what your part is for and how it will be used. We can say with confidence that better than 2768-1 fine is rarely necessary and that you’ll save time and money and still get a great part if you use the above suggestions as a guideline. When you’re ready to know more our engineers are standing by to help with technical information when you submit your drawings for a quotation.