Blog

Star Rapid’s blog aims to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

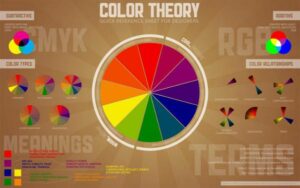

Everything You Need to Know About Color

How many colors are there? Most people can see more than ten million distinct colors, hues, shades and tints. That’s a large palette to choose from. In order to get the most benefit from using color in product design, we’ll first explain color theory and terminology. Then we’ll explore ways

The Art of Inspecting Material

Manufacturing high-quality parts requires using high-quality material. Find out how Star Rapid tests all incoming material before manufacturing.

How We Test And Control Color

Why Is Color Important? Successful products need to stand out in a crowded marketplace. One way to do this is with a great paint job or molded-in color. With modern paints and pigments, there are millions of colors to choose from. Colors attract attention, establish brand identity, differentiate your product,

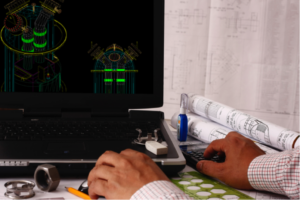

Understanding Accuracy, Precision and Tolerance To Improve Product Design

Computer Aided Design (CAD) software is now the default tool for drawing perfectly rendered objects on a computer screen, which are then transferred to a manufacturer to make the actual part. But there’s a danger in thinking that anything that can be designed can just as easily be made. Software

New Process to 3D Print Metal For Mass Production

The Direct Metal laser printer uses binding jet technology in a new way to make fast, high volume 3D printed metal parts for mass production.

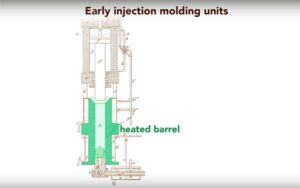

The Importance Of The Reciprocating Screw In An Injection Molding Machine

The single greatest innovation in the 20th century for improving plastic injection molding comes from one of history’s original and most basic machine types: the screw. Let’s take a closer look at the ingenious application of this simple design and how it improves the plastic injection molding process. How Was