Electronic devices of every kind are integrated into our daily lives. Their functions vary but they all depend on packaging and enclosure solutions that are lightweight, durable, convenient to use and with designs that can be quickly transitioned from prototypes to volume production in response to rapidly changing market conditions.

To meet the requirements of the electronics industry, Star Rapid has multiple manufacturing services available in one location. We offer pressure die casting, CNC machining, polyurethane vacuum casting, and plastic injection molding – including micromolding – to make enclosures or accessories for electronic devices in a wide range of materials and surface finishes.

Get to market faster by contacting us to see how we can help you manufacture your consumer products.

Our team of international managers and engineers have experience working with some of the world’s most prestigious electronic equipment manufacturers. Not only do we offer world-class manufacturing services to support you in our ISO 14001 and OHSAS 18001 certified facility, but we also offer complete raw material verification through our advanced incoming material testing laboratory. This is crucial for meeting the stringent safety certification requirements for electronic and other powered devices.

We also appreciate that you need agile manufacturing solutions when bringing new electronic products to market. To support you Star Rapid has no minimum order quantities or minimum order values. You can invest your resources in developing rapid prototypes and then quickly transition to rapid tooling and larger volumes when you’re ready.

Our micromolding machines can produce hundreds of parts at a time, in a single mold, each as small as one gram.

On our 1,000 ton injection molding machine, we can mold a single shot of more than 4 kg.

We’ve worked on automotive sensors, medical wearables, satellite telecommunications, electronic security and many more.

Many great products start out as prototypes that are used to test the fit and function of a design, and transition from a few engineering models to eventual mass production.

Polyurethane vacuum casting is one of the most valuable rapid prototyping methods. Not only is it fast and economical, but the quality of the copies is equal to that of regular production parts – without the investment in hard tooling.

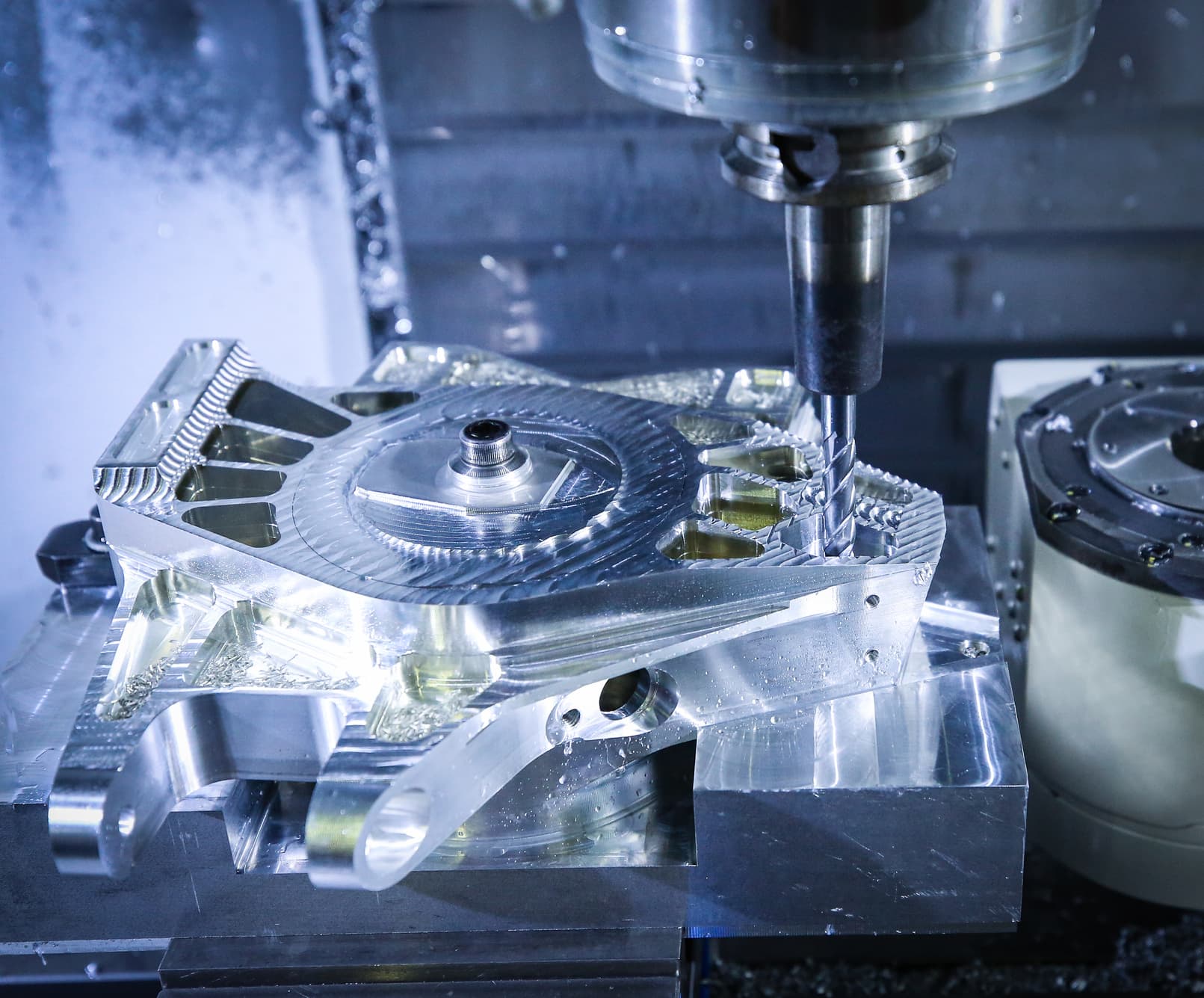

Advanced multi-axis CNC machines produce unlimited volumes of finished parts from virtually any commercially available raw stock, and they do so quickly and with great accuracy.

We use CNC machining to make enclosures as well as engineering-grade fittings in support of electronic devices made from a wide range of ferrous and non-ferrous metals as well as hard plastics.

When it’s time to ramp up to larger volumes in metal, there is no better solution than pressure die casting.

We provide pressure die casting in capacities from 160 to 1300 tons. This means we can make cases in aluminum, magnesium or zinc for electronic products that need to be in strong and corrosion-resistant housings. Pressure die casting is also a common way to make heat sinks for higher powered electrical devices like transformers and audio equipment.

Our injection molding capacity ranges from 10 ~ 1,000 tons. We are also able to provide micro-sized battery cases, light pipes, mechanical components and fittings for the miniature electronics market. On the larger end of the scale, we regularly make plastic housings and other components up to 800 mm on a side – big enough for the most ambitious applications.

In addition we also machine our own standalone mold tools in P20, NAK80, H13 and S136 steel. And we can offer P20 rapid tooling at the same price as aluminum 7075.

Subscribe to our Newsletter for the latest news, updates and offers.

Star Rapid Manufacturing, 2017. All Rights Reserved.