Metal 3D Printing For Conformally Cooled Mold Tools

Services: CNC machining, EDM machining, metal 3D printing, plastic injection molding

Materials: Maraging Steel, Tritan TX2001 Copolyester thermoplastic

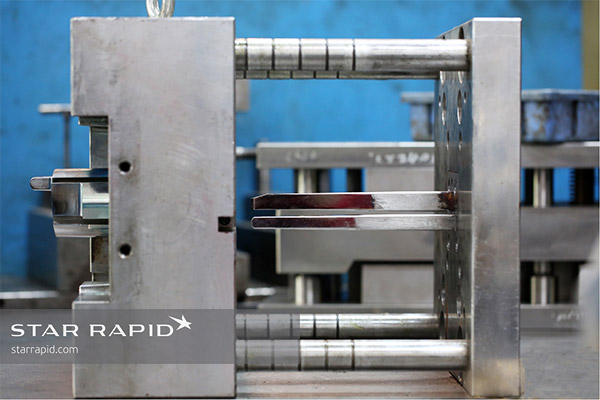

Qty: Conventional core with two inserts, conventional core with two 3D printed inserts, 3D printed core and 3D printed inserts

What is Conformal Cooling?

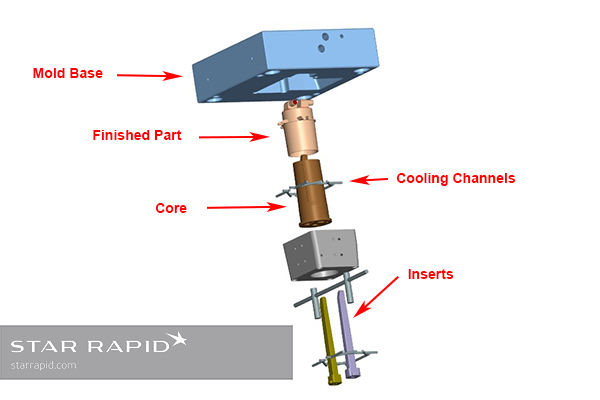

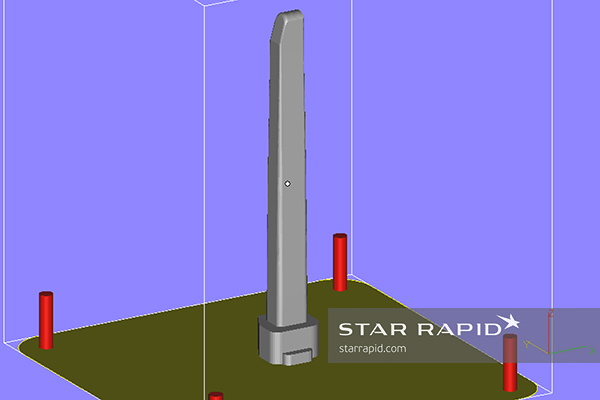

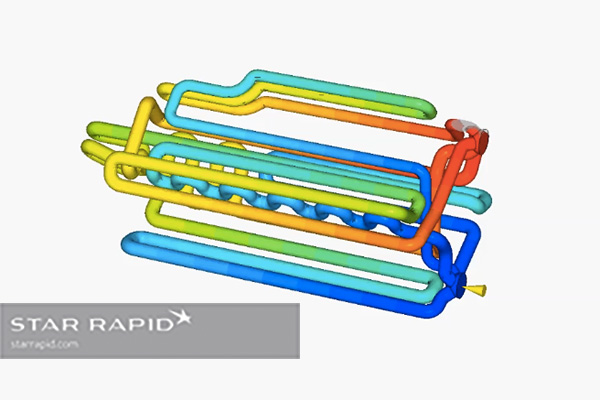

For all plastic injection molding jobs it’s important to control heat. In a conventional mold tool, heat is controlled with coolant that flows throughout the mold in linear channels. These paths are made by drilling straight holes, and they have their limitations when molding complicated shapes. To improve this process, we’ve been conducting research and development to explore conformal cooling using metal 3D printing.

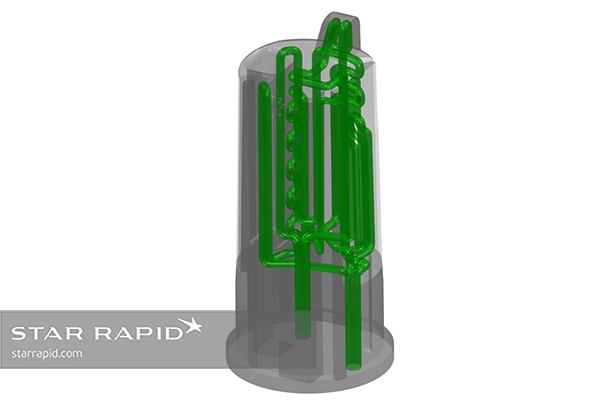

Conformal cooling means that the channels can be designed to follow the shape of the part. These channels “conform” to any shape for optimum efficiency. Due to the limitations of subtractive manufacturing, only 3D metal printing can make them.

About The Project

Our team at Star decided to start researching conformal cooling to test how it can provide our customers with an even faster and more competitive service. We partnered with our clients at Marco Beverage to remake their hot water reservoir using conformally cooled plastic injection molding tools. We felt that conformal cooling would further improve their product so it made a great candidate for further study. The reservoir is a clear plastic dispenser used for high-end water boiling and coffee making machines. You can read about how the original prototypes were made in this case study.

Partnering with Renishaw

To conduct the research, we partnered with Renishaw, the maker of our DMLM AM250 powder bed printer. They provided engineering support for the technical design of the 3D printed core. Working closely together, we created a solution that greatly reduced the cycle time while improving quality. This case study presents our findings and shows how conformal cooling can enhance the performance of plastic injection molding tools.

Project Part One

To measure the effectiveness of this approach, we first tried to maximize the performance of our conventional mold tools. This would establish a benchmark for later improvements.

Material Verification

As with all of our projects, we used our advanced metrology equipment to verify that we had the right material. This is especially important for medical devices that must pass rigid FDA guidelines.

Our PolyMax gun employs a laser to compare the molecular signature of the sample with a database of known resin types.

Challenge

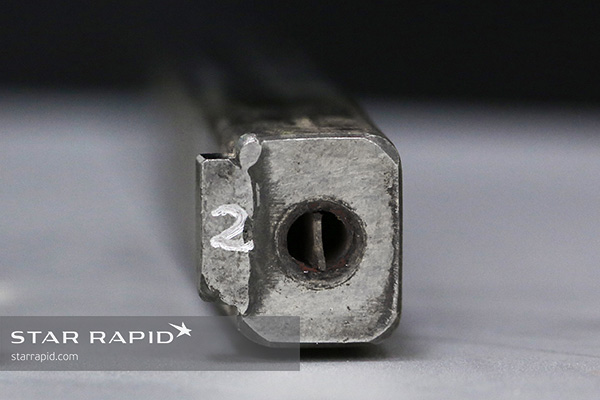

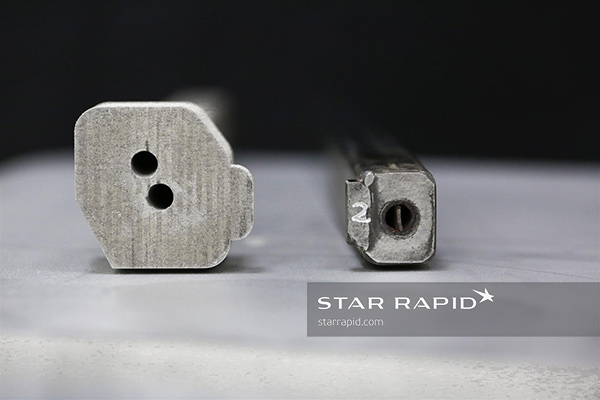

To make the internal water supply columns for the reservoir that are such an integral part of this design, two molding inserts were required. In the conventional tool the cooling channels were drilled out and a baffle inserted not quite to the end of the hole. This left a gap at the bottom, creating a return circuit for coolant. You can see that the size and shape of this channel is not ideally suited to the insert’s outer walls where the coolant is most critically needed.

Test Results

| TEST ONE | TEST TWO | TEST THREE | |

|---|---|---|---|

| INJECTION TIME | 40 sec. | 40 sec. | 40 sec. |

| COOLING TIME | 60 sec. | 60 sec. | 22 sec. |

| MANUAL COOLING | 90 ~ 120 sec. | NA | NA |

| WATER PRESSURE | 5 Pa | 5 Pa | 5 Pa |

| INITIAL WATER TEMP. | 14 deg. C | 15 / 20 / 60 deg. C | 15 deg. C |

| TOTAL CYCLE TIME | 100 sec. | 100 sec. | 66 sec. |

Details of Test One

After several cycles, the water temperature at the insert location rose from 14° C to 65° C. This created a visible “lake mark”, which is a pooling effect created when hot plastic continues to flow after the mold is opened.

Corrective Action One

To cool the mold, compressed air was blown onto the inserts for 1 ½ minutes before removing the part. This lowered the temperature to approximately 35° C. The resulting parts had a slightly improved surface finish, but still some distortion. For volume production this extra time would add significantly to cost.

Corrective Action Two

To further cool the inserts, compressed air was sprayed on it for 2 minutes, reducing the temperature to approximately 30° C. This once again improved the finish quality slightly, but it was far from ideal.

Project Part Two

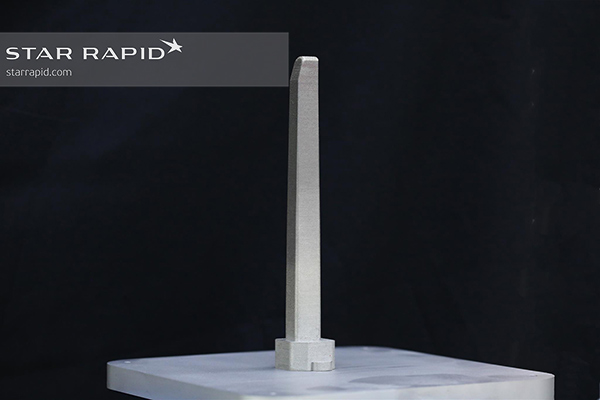

It was decided between ourselves and Renishaw to use metal 3D printing to make new inserts with conformal cooling channels. These would take longer to produce than their conventional counterparts, but the costs can be recouped over time by improving cycle times and product quality, thereby lowering production costs for large volumes.

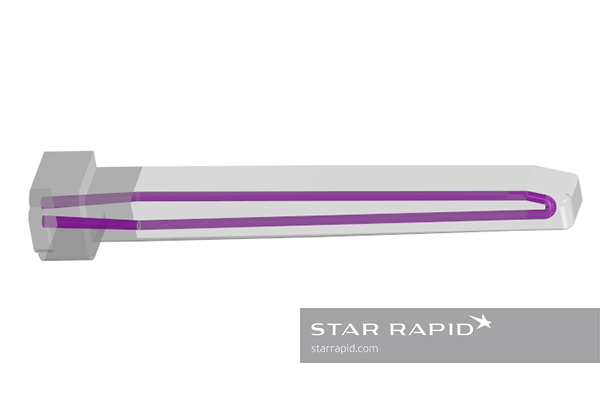

The conformal cooling channels were designed to closely follow the contours of the part, while staying close to the internal walls of the tool for greater efficiency.

Test Two Parameters

For the second series of tests, the input water temperature was stepped up in increments, from 15°to 20° to 60°. This was an attempt to equalize the temperature differential between the molten resin and the mold.

For each increase, we recorded the resulting temperature at four places: the 3D printed inserts, the core, the mold base and the mold cavity. These recordings were taken on the 1st, 4th and 8th cycles respectively.

Details of Test Two

The 3D printed inserts, the mold base and the cavity maintained a temperature consistent with the corresponding input water temp., with only a 1~2° C fluctuation.

However, the temperature of the core increased more than 25° C above the water supply temperature. It became apparent that this was the primary cause of the heat-related defects on the surface of the plastic. To address this problem we decided to make 3D printed conformally cooled cores.

Project Part Three

Two different CAD designs were created for the cores – one by Star Rapid’s engineers and one from LBC Engineering. LBC specializes in advanced design solutions for complex 3D printing challenges.

Heat Mapping

Details of Test Three

Finishing

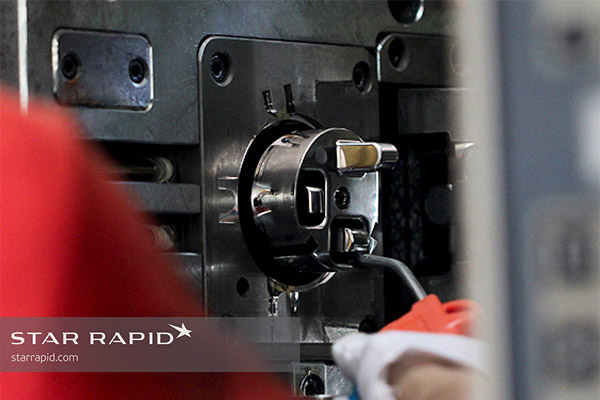

Once the final dimensions were verified, the surface finish was given a high gloss in our model shop.

The Advantages of Conformal Cooling

With the new injection mold tools we conducted a series of test runs to gauge our results. We found that the 3D printed cores and inserts performed significantly better than conventional mold tools. How much better?

Not only was conformal cooling able to help us greatly improve the product quality, but we also reduced the cooling time by 38 seconds, or 60%. This completely removed the need for additional manual air cooling.

This reduction in cycle time can be a significant cost-savings for longer production runs, and may go a long way to offsetting the relatively larger expense that comes from developing such a tool. We will continue to work with Renishaw and LBC Engineering in the future to refine this process for future advanced applications. Want to know more? Upload your CAD drawings for a free quote or contact us to talk with one of our specialists.

Star Rapid no longer offers metal 3D printing services. However, we remain fully committed to helping our customers reach their product development goals by offering a variety of rapid prototyping and low-volume manufacturing services.

If you are looking for metal 3D printing tips, check out our online video tutorials.