Quix Powered Exoskeleton Controller Case Study

Services: CNC milling, CNC turning, Bead Blasting, Anodizing

Materials: 6061 T6 aluminum, 416 Stainless Steel

Qty:Eight Sets (total of 224 parts)

About IHMC

Star Rapid has worked with the Institute for Human and Machine Cognition (IHMC) for several years, helping them to produce custom components for robotics, exoskeletons, & human robotic interdependence.

IHMC is a pioneer in human- machine interface technology. In their words:

“These devices encompass a vast array of applications including mobility assistance for spinal paraplegic injuries, strength amplification for able-bodied users, and compact resistance exercise for astronauts in space.“

The Project

IHMC needed eight complete sets of components for their Quix lower-body powered exoskeleton. This exoskeleton provides mobility assistance for paraplegic users and is the successor to the MinaV2, which competed successfully in the Cybathlon competition in Zurich, Switzerland two years ago. Star Rapid was proud to have also helped with that earlier project, which you can learn about in this case study.

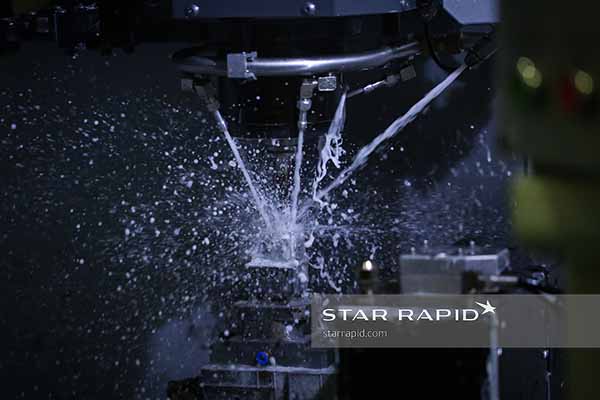

CNC Milling

All of the structural parts were made from Al-6061 T6 aluminum. This material is strong, lightweight and is an excellent substrate for anodizing. The original plans called for using Al-7075, which is a stronger grade of aluminum, but 7075 does not take anodizing as well.

CNC milling is ideal for making the complex geometries of this carriage. In this photo, the coolant has been turned off for clarity but in normal operation the part will be bathed in a steady stream of cutting fluid to control heat, lubricate and wash away waste material.

Multi-axis CNC milling is the only reliable way to make parts with complex compound curvature.

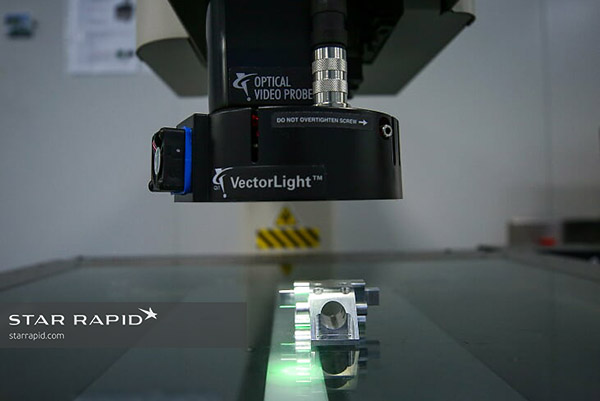

Measurement

This part is difficult to measure conventionally, so we used our 3D optical scanner to qualify all critical dimensions and tolerances.

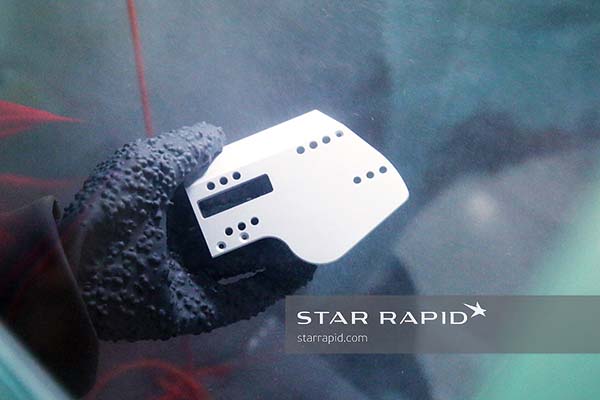

Surface Preparation

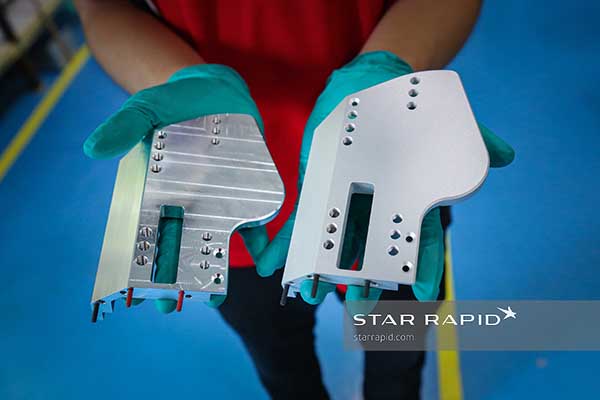

After a part is freshly machined it still has sharp edges and characteristic tooling marks, such as on this side plate. This surface needs to be prepared before it’s ready to be anodized.

We used bead blasting to remove these marks and sharp edges.

Bead blasting creates a uniform surface finish with no sharp edges.

A matte finish like on the right hand side is perfectly fine for some projects, but on raw aluminum it will oxidize over time and should be protected with a paint film or anodized coating.

CNC Turning

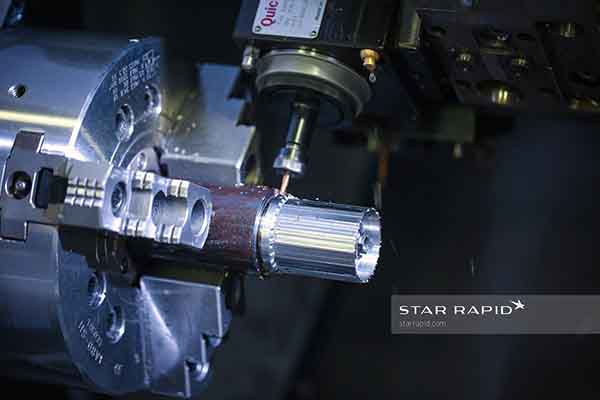

We also made a set of rotors for the exoskeleton, which will be part of the electric servomotors to control its motion.

These rotors were made from 416 stainless steel. Although not quite as corrosion resistant as other grades of stainless, 416 is “free machining”, making it easier to turn, drill and thread. It is also magnetic, which is necessary in an application where electrical current is used to drive the motor.

We used our Haas turning center to make both the internal and external diameters of the cylindrical rotor.

One of the great advantages with our turning centers is that they can use live tooling. This means that cutting tools mounted on independent spindles are able to create features perpendicular to the main axis of rotation. Here we are milling flat faces on the circumference of the rotor which are used to index its rotational motion.

These rotors also needed to be machined from both ends. That required us to dismount, rotate and re-mount, while still maintaining the correct tolerances.

Anodizing

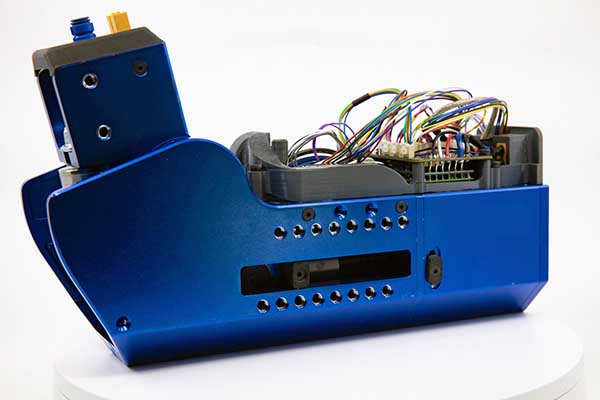

After milling and bead blasting the structural aluminum parts we then anodized them. Anodizing is attractive, prevents corrosion and creates a very hard layer of aluminum oxide on the surface to help prevent scratching and wear.

Anodized parts must be thoroughly cleaned and etched with strong chemicals to prepare them.

Anodized parts must be mounted on a fixture or tree so that they can be immersed in the chemical bath without touching the walls of the container. This means that any place in contact with the tree will also not be anodized.

Dyes are added to the electrolyte to create this blue color. This dye is actually sealed in myriad pores below the surface, so it is very durable.

This year’s Cybathlon event has been rescheduled due to the ongoing CoVID-19 crisis. However, the Quix exoskeleton is undergoing continuous testing and development regardless. We are proud to continue to partner with IHMC on next-generation mobility solutions. We have other case studies where you can learn more about how we are working with innovative engineers for medical research and health diagnostics. We look forward to working with you when you upload your CAD files for a free quotation and project review.