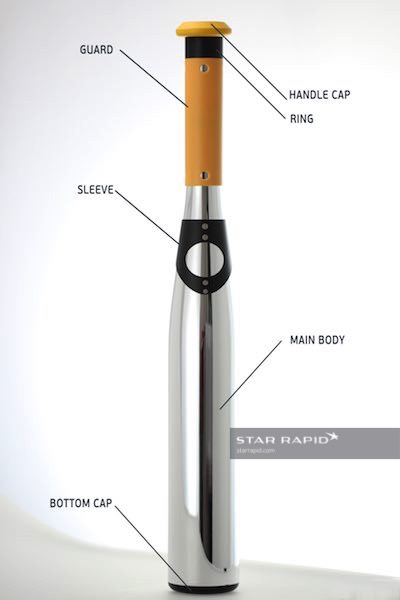

Smart Bat Case Study

Services: Mold Making, CNC machining, Vacuum Casting, Painting, Chrome Plating, Pad Printing

Materials: ABS plastic, HDPE plastic, UPX8400 polyurethane

Lead Time: 10 days

Quantity: One

Cost: ~1500 USD

About The Product

The Smart Bat is a prototype developed as the thesis project for a Master’s Degree in Industrial Design. Meant to be used as a fitness training aid for public school students, the bat contains accelerometers to measure swing speed and position, while an embedded wireless chip connects to a wearable sensor that allows each student to monitor their performance, upload stats to a mobile app, and collect prizes as determined by their school’s incentive program.

About The Designer

The designer of this smart bat, Nyasha Chawora, is a 4th year MDES (Masters of Design) Consumer Product Design student at Coventry University. He is a passionate product designer and hopes to carry on the skills and experience gained at University and his travels in China. This particular project’s title is “Childhood Obesity! How can design help children be more physically active?”

About The Project

Coventry University had already determined a list of major design challenges and ‘obesity and fitness’ was chosen by Nyasha as the focus of his thesis. To complete his project he needed a prototype as a proof-of-concept, so he turned to Star to help him bring it to reality. Prior to this Nyasha had no experience in manufacturing but spending time at the Star factory in China gave him invaluable insight into designing for manufacturing, which he hopes will inform his future work.

How The Parts Were Made

Making The Main Body

The body of the bat was machined in two separate halves from a solid block of ABS plastic, which is lightweight, strong and easy to work. Once machined, the halves were cut free from the base substrate and glued together. The now single body was carefully hand sanded to remove any parting line, then given a coat of primer to seal the surface. Later it was chrome plated to provide the distinctive metallic look.

Making The Rings, Sleeves, Guards And Caps

We cast the ring and sleeve from soft polyurethane UPX8400. To make vacuum casted copies we must first make a master mold from silicone, which is formed around a solid pattern. That pattern, in turn, is created using stereolithography (SLA), a 3D rapid prototyping process.

The SLA masters were hand-sanded until smooth.

These masters were then used to make a vacuum casting out of silicone rubber.

Once the silicone cures around the master, it is carefully cut free in two sections and the master removed, leaving behind a void with is the exact negative image of the desired finished piece. Into this void is poured the polyurethane. Silicone molds of this type are inexpensive and are robust enough to make 20 or so perfect copies of the original.

After printing, we removed the SLA prototypes from the build platform, which contains support structures that must also be removed. The prototype will usually be rough and must be carefully hand sanded until smooth.

Inside of a casting box, we poured liquid silicone around the master model and cured it in an oven. After curing, the silicone is separated in two sections and the master removed, leaving behind a cavity which is the exact negative image of the desired finished piece. To cast copies, we pour liquid polyurethane into the cavity. Molds of this type are inexpensive, quick to make, and durable enough to make 20 or so copies of the original.

Finishing

Nyasha had a personalized logo, so from this design we made a stencil and pad printed the logo onto the ring of the bat. Finally, we made an end cap from black high-density polyethylene (HDPE). This was CNC machined, as was the bat handle and knob, and all three were painted yellow to match the color of the guard.

Read about other projects we’ve worked on or, if you’re ready to get started on your latest project, contact us for a free project review.