Star Rapid

Why Choose Star Rapid® for Aluminum Extrusion?

Used in industries ranging from construction to consumer electronics, aluminum extrusion is a manufacturing process in which aluminum alloy is pushed through a die with a specific cross-sectional profile. Both fast and straightforward, aluminum extrusion yields products that are lightweight, strong and resistant to corrosion. Here are several reasons to choose Star Rapid for aluminum extrusion services.

An Experienced Team

We have experienced engineers and project managers on-site to oversee your project, while an international sales team is at your service and in your region to facilitate fast and clear communication every step of the way.

Star Rapid

Services to Complete a Wide Range of Projects

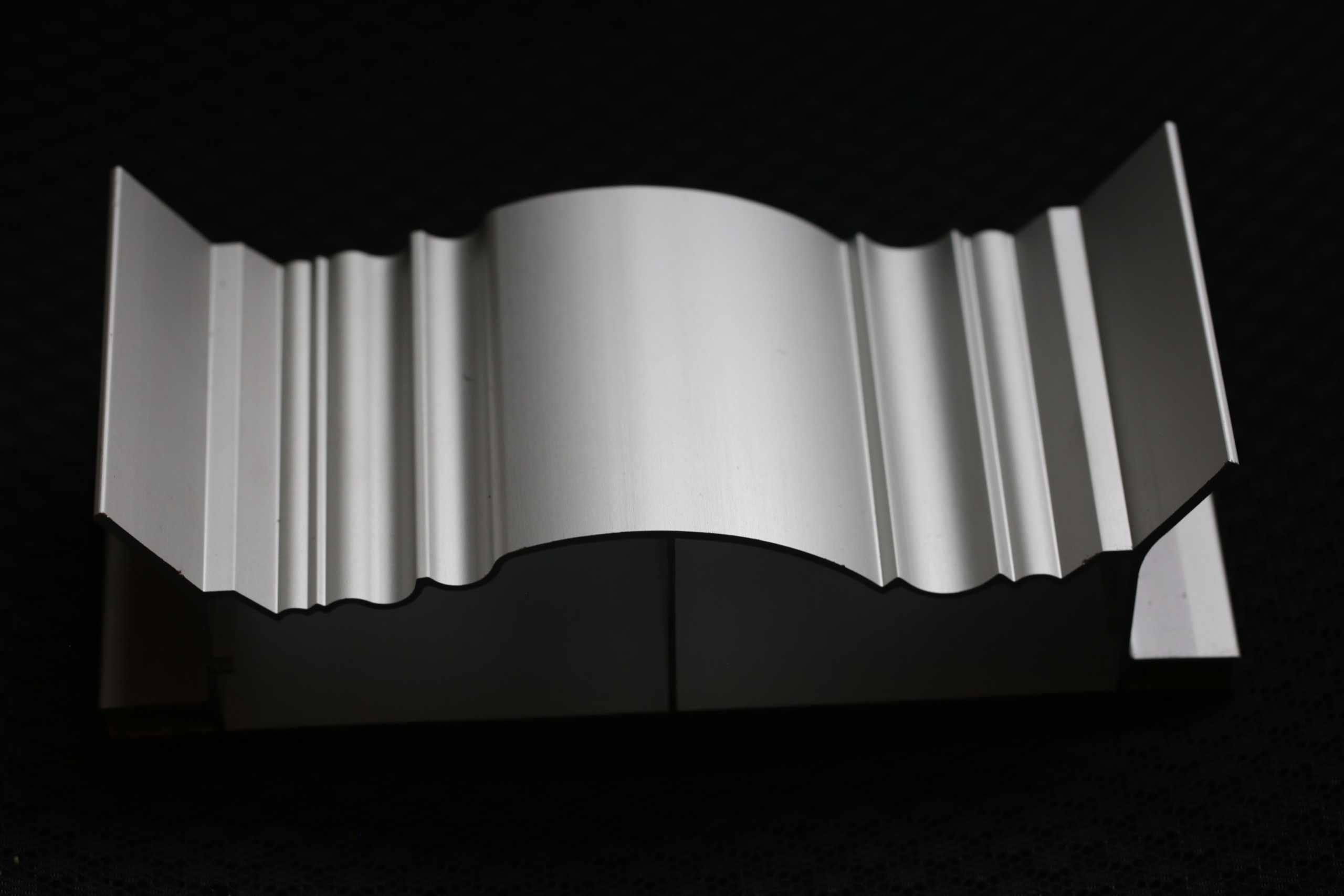

Our advanced machinery allows us to make box-section and open-channel dies with dimensions ranging from 185 square millimeters up to 275 x 60 millimeters. We can also make complex extrusion profiles with finished lengths up to 5 meters.

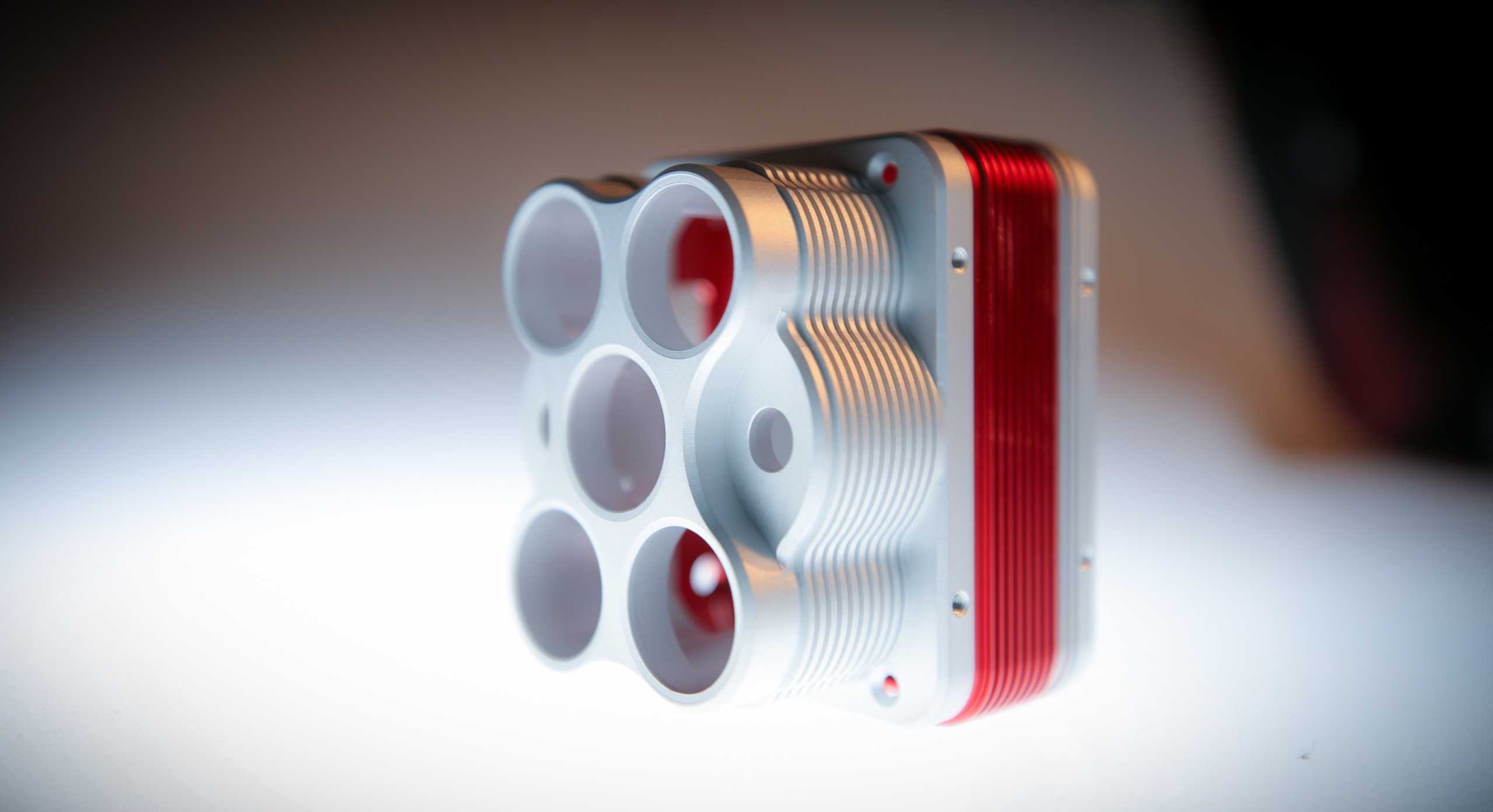

To complement our aluminum extrusion services, we also provide multi-axis CNC post-machining services, such as hole drilling and tapping. Wire EDM is also available for short-run orders that don’t need a dedicated extrusion die.

On-Time Delivery with Tested Performance

Working to complete projects on-time and on-budget, we have 2- to 48-hour response times on RFQ’s 95% of the time, as well as a 90%+ OTD (on-time delivery) against our commitments. We also have robust quality control and quality assurance processes, which help ensure that our finished products work the way they’re supposed to.

Investment That Matters

We’re passionate about our people and processes, which is why we’re always investing to improve them. We’ve implemented a Star University program of mentorship and training to ensure our personnel have the skills they need to be the best in the business. And we are always upgrading our facilities and equipment to stay at the forefront of advanced manufacturing.

Related Blog Posts

Star Rapid provides best-in-class low-volume manufacturing services. Learn how we can support you on your next project.

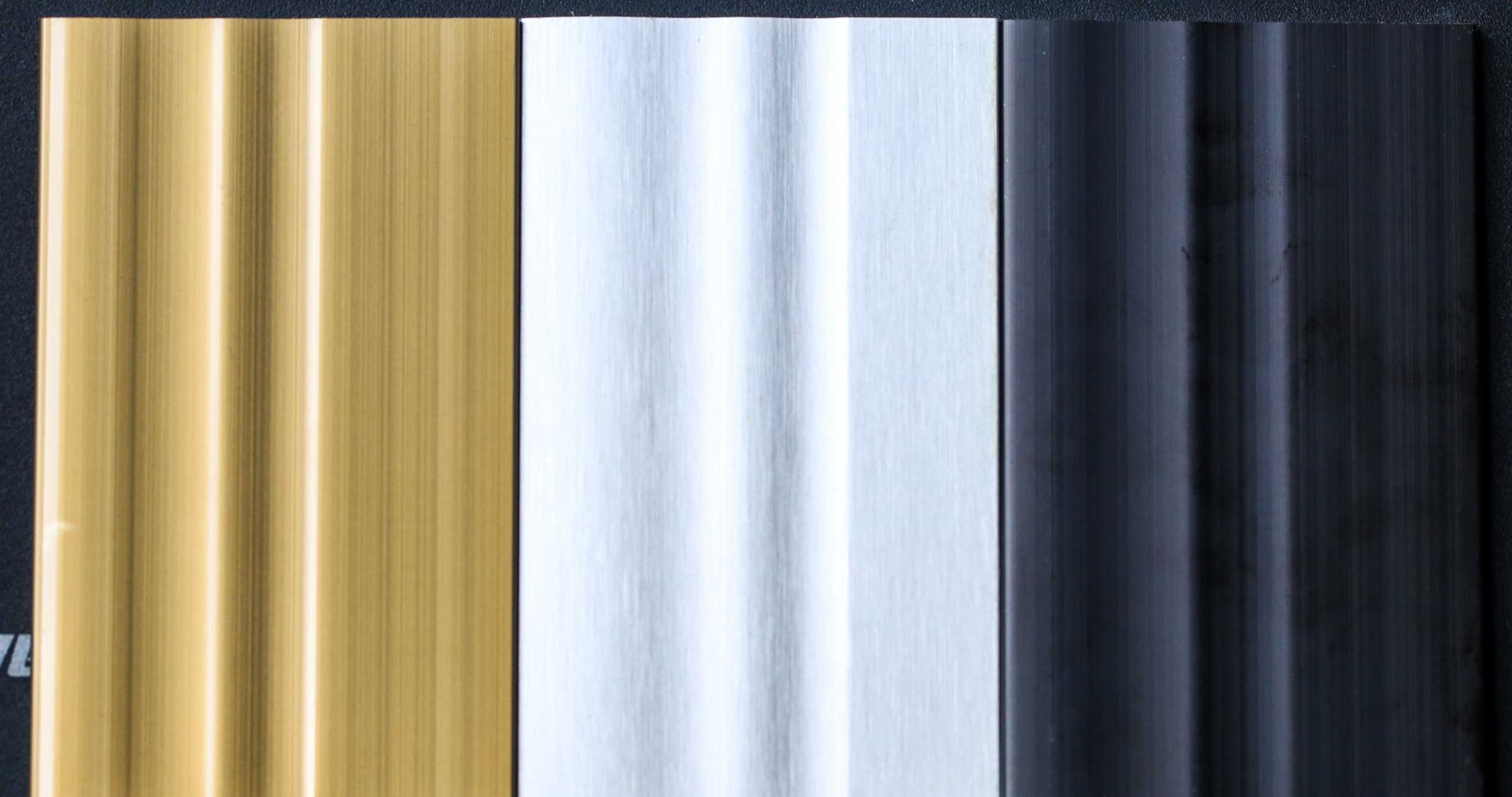

Anodizing is a method for changing the surface chemistry of metals and other substrates. It protects against corrosion, enhances aesthetic qualities, resists scratching and is one of the most durable surface finishes available. Anodizing can be done on a range of materials, but today let’s look at aluminum. These 8 questions will help to show why anodizing is a clever surface treatment that’s both practical and beautiful.

There are hundreds of metal alloys available for CNC milling and turning. Which one is best for your next project depends on a number of factors, including price, workability, corrosion resistance, strength, weight and cosmetic appearance. To help you choose, here’s a closer look at the ones we use every day and what benefits they may have for your next project. Click the button below to get the inside scoop on the right material to choose for your product.

Star Rapid

Turning Ideas Into Reality

What Does Star Rapid Offer?

We make box-section and open channel dies in sizes ranging from 185mm² up to 275 x 60mm. These dies produce complex extrusion profiles in finished lengths up to 5 meters. We also offer Multi-axis CNC post-machining including hole drilling and tapping. Wire EDM is available for short-run orders of complex profiles that don’t require a dedicated extrusion die. We control all post-processing operations according to your exact specifications. This includes polishing, anodizing, painting and powder coating to complete your parts.

Aluminum Extrusion Tolerances

We follow the standard general NADCA tolerances. However, if your requirements are very precise, then the precision tolerances standard can be followed once we have confirmed your designs.

Specifications

- Press sizes: 450T ~ 3000T

- Minimum order volume: 0.5 ton aluminum for smaller machines, 1.0 ton of 6063 aluminum for larger machines.

- Tooling lead time: 2 weeks for small molds, 4 weeks for larger molds.

- Post-machining: Full service CNC cutting, threading, slotting, face milling, etc.

Further Reading

Improving Looks And Performance With Anodizing

Want to know why anodizing is one of our favorite forms of surface treatment? In this video from Serious Engineering, Gordon Styles breaks down the many benefits of anodizing for aluminum, magnesium and titanium parts.

Anodized Aluminum Colors: Understanding Color Matching

A Walkthrough of the Aluminum Anodizing and Color Matching Process Anodizing is a great way to put an attractive and physically durable finish on aluminum parts. Anodizing improves corrosion resistance, surface hardness, prevents scratching and

What Makes a Great Paint Job

When people think of paint, they tend to think of it in a general sense. They often picture a smooth liquid substance that—once applied to a surface—can bring walls, buildings, and furniture to life. The

Get Your Aluminum

Extrusion Project Started Today

After receiving your drawings, our engineers will analyze your custom aluminum extrusion molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.