Five Rapid Prototyping Solutions For Great Results

Ever since people started making stuff – and then tried to make new and improved stuff – there’s been a need for prototypes. They’re used

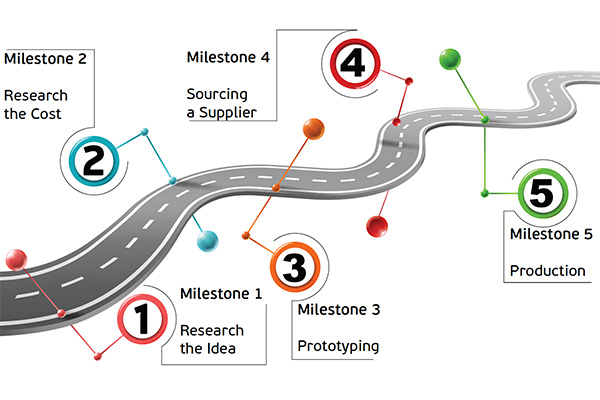

Rapid prototyping means making a physical sample of a new product design idea. This is done as a preliminary step towards eventual production, and is most useful when verifying that the finished product will look, feel, and perform as intended. New product developers turn to rapid prototyping for several reasons. They’re used for functional testing, approvals, design iterations, for crowdfunding campaigns, trade show models, and as a bridge to low-volume manufacturing.

Prototypes often inspire re-designs, improvements, and other modifications that may not have been obvious merely from a computer graphic, so in this regard they’re beneficial for optimizing a design before committing resources to larger volumes. In fact, being able to correct design errors early in the development phase can more than compensate for the cost of the prototype itself, so they’re wise investments.

Any physical model can potentially be a prototype. The difference lies in how closely it reflects the intended finished part.

Very simple models can be made with paper, plastic, modeling clay, styrofoam, balsa wood, or other common household materials. These are examples of very low-fidelity prototypes, but they do have the advantage of being easy and inexpensive to make.

These types of prototypes would likely not function very well or for long, so they’re used primarily to get a visual idea of the design and to compare it in scale to other parts.

More high-fidelity prototypes use modern machine tools and materials, including various 3D printing technologies, vacuum casting, rapid tooling for injection molding, and CNC machining.

Prototypes often inspire re-designs, improvements, and other modifications that may not have been obvious merely from a computer graphic, so in this regard they’re beneficial for optimizing a design before committing resources to larger volumes. In fact, being able to correct design errors early in the development phase can more than compensate for the cost of the prototype itself, so they’re wise investments.

The right prototyping method is the one that best fits your budget, the complexity of the part, what you want the prototype to do, and your development timeline. Better prototypes cost more money and take longer to make, but they also more faithfully represent the form, fit, and function of a production part.

The basic questions to ask are these:

There are many variables to consider and we cannot cover them all here.

How can partnering with Star Rapid to quickly manufacture a prototype help you and your business? Here are a few ways:

Show your customers and investors a physical model of your product

Demonstrate the appearance, dimensions, and features of your product

Test the market with your product before production

Improve and streamline the production process

Create multiple versions with different colors, surface textures, and finishing processes

There are three common rapid prototyping services Star Rapid provides.

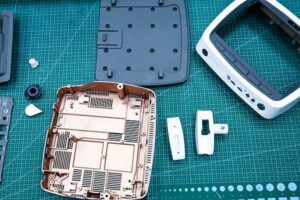

CNC machining is an excellent way to make high-fidelity, end-use prototypes from a variety of raw materials. It’s fast, accurate, and versatile. It’s also easy to make minor changes to the cutting program in order to perfect the final product. CNC machining can also make tapped and threaded holes, which can’t be done with other methods. CNC machined prototypes are full strength, so they’re suitable for engineering testing.

Finally, it’s possible to make small numbers of housings and enclosures without investing in expensive plastic injection mold tools. However, product developers should note that the corner radii of a machined part will not be the same as a corner made from an injection mold tool. There may be other slight design differences as well, so it’s best to consult us in advance.

Polyurethane vacuum casting molds create up to 30 high-fidelity copies from your original master pattern. Parts can be molded in a variety of resins, including engineering grade plastics, and even overmolded in multiple materials. Vacuum casting is often used as a substitute for plastic injection molding because it is ideal for small volumes of hollow cases and enclosures.

We’re experts in making production quality cast copies from master patterns.

Not only will you benefit from our exceptional attention to detail, but we also provide a full suite of finishing services to bring your part up to showroom quality. Learn more about what our vacuum casting service can do for you.

Our rapid tooling service supports you with high-quality plastic injection mold tools that can be made in as little as two weeks. If you need prototype cases and enclosures for your project, rapid tooling might be the solution. Talk to our engineers to receive a free design for manufacturing review.

Rapid prototyping doesn’t involve a single technology or process. Any of the same manufacturing techniques used to make prototypes can also apply to regular production volumes. The value comes from making a physical model that closely resembles the design intent, is durable, can be produced quickly, and with a minimal investment in tooling or raw materials.

Making a quality prototype is an important first step in your product development journey. We’re veterans in rapid prototyping and we can help you to make your design dreams come to life.

We’ve helped hundreds of clients, from private inventors to large corporations, create stunning prototypes that exceeded their expectations, and we can do the same for you.

We’ve invested in the finest raw materials and equipment so you get superior rapid prototypes that look and perform like full-production parts, but in a fraction of the time and cost.

Our proprietary AI quoting algorithm ensures you receive fast and accurate quotations to help you reach your product development goals while managing your budget.

Most quotes are delivered within 24-hours, or less, depending on the project details. Your customer support partner will contact you directly to ensure that you’ve received and understand all aspects of your quotation and to answer any questions you may have!

Star Rapid provides best-in-class rapid prototyping services. Learn how we can support you on your next project.

Our partners at BioRep needed a quick-turnaround solution to make stem cell isolators in the fight against Covid-19. Star Rapid responded in a matter of days.

Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances. Read the case study by clicking the learn more button below.

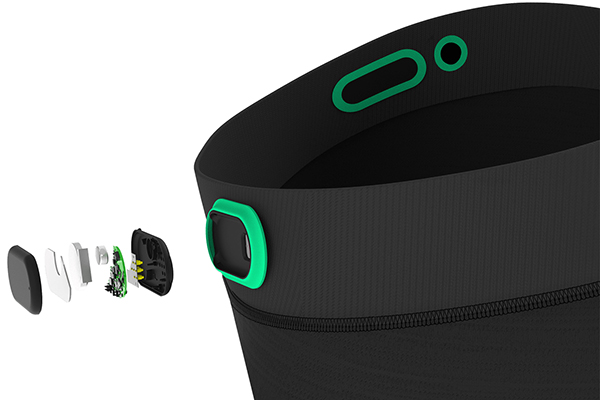

Myant approached us to help them develop a set of rapid prototypes for their major product introduction at CES 2018. These prototypes needed to be showroom quality, identical in fit and finish to eventual production versions. Time was limited, so we advised using SLA 3D printing to make a set of master patterns, from which we could then make multiple copies using polyurethane vacuum casting. This method is one of the fastest and least expensive ways to make rapid prototype copies in plastic without making hard production tools.

When you’re ready to take your design from rapid prototyping to volume production, Star Rapid offers a range of solutions that are agile and easily scaled. We have no minimum order volume restrictions, so our lean manufacturing services are an ideal solution for bringing new ideas to market on your schedule. Learn more about the benefits of low-volume manufacturing and how we can support your prototyping to production needs.

Our improved algorithm decreases rapid prototyping quotation times by up to 90%. Most quotes are delivered within 24 hours or less, depending on project details. Your customer support partner will contact you directly to ensure you’ve received and understand all aspects of your quotation and to answer any questions that you may have.

Ever since people started making stuff – and then tried to make new and improved stuff – there’s been a need for prototypes. They’re used

Rapid prototyping means building a physical model of a new product design as quickly and as economically as possible. Some prototypes will be used merely

Virtually all new products intended for the medical industry start out as prototypes. Prototypes are used for proof-of-concept, engineering testing, certifications, benchmarking and as design

Subscribe to our Newsletter for the latest news, updates and offers.

Star Rapid Manufacturing, 2017. All Rights Reserved.